(1729) Questech: Sealed Bid Offer

Online Auction Closes: Tuesday, March 3 @ 12PM (EST)

Preview Date: Inspection by Appointment

Location: 92 Park Street, Rutland, VT 05701

Contact us for preview appointment:

helpdesk@thcauction.com or call 802-888-4662

Item Removal Date: Monday-Friday, March 9 - March 13 from 8AM-5PM

Have a question or want to attend the preview?

Email or Call us at: helpdesk@thcauction.com | 802-888-4662

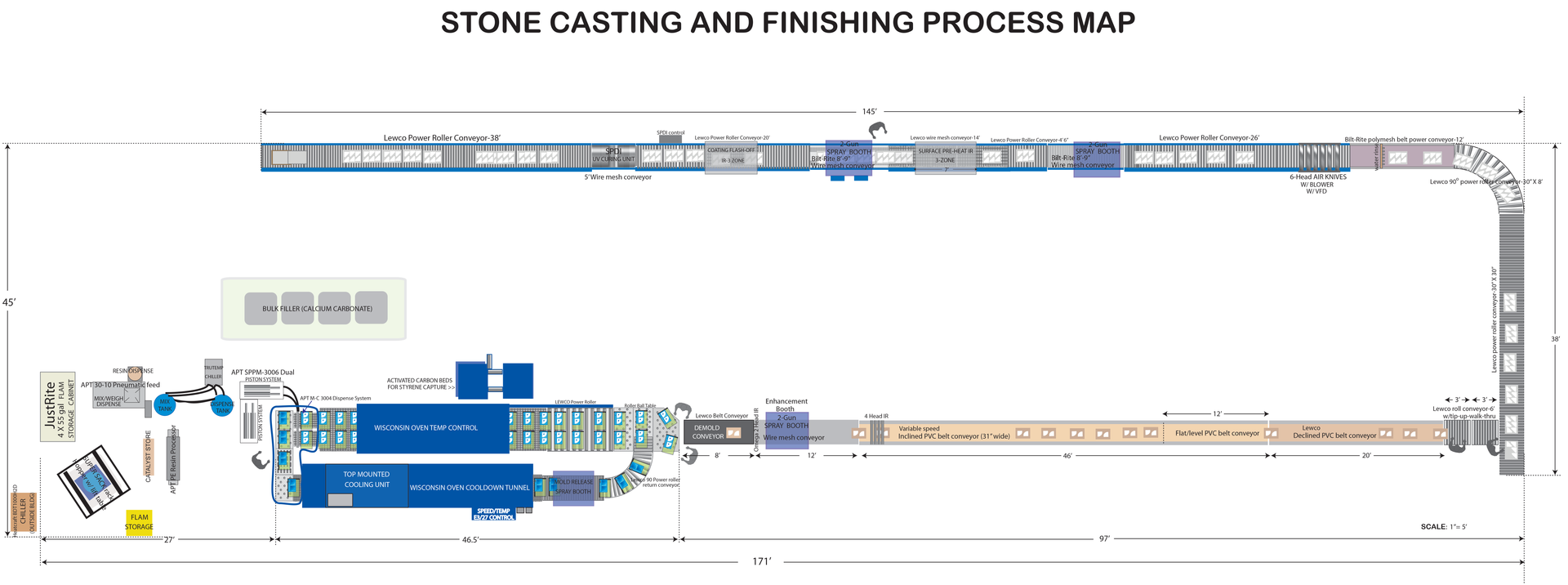

Lot #1: Semi-Automated Cast Resin "Metal" Production Line

Lot #2: Semi-Automated Cast Resin "Stone" Production Line

About this Auction

Tile and Bathroom Accessory Manufacturing Plant

Sealed Bid Offering and Timed Online Auction

We have been retained by Questech ABC (Questech Corporation), manufacturer of cast tile and bathroom accessories, to sell the manufacturing and material handling equipment and the intellectual property.

The initial offering will be by sealed bid with the lots being: the (2) product casting lines in their entirety, the Formula 131 IP & inventory and the Questech Corporation IP. Following the closing of the sealed bid offering, a timed online auction of the remaining machinery and equipment will take place. Anything going unsold through the sealed bid process may be include in the timed auction. A partial list includes:

Preview Location:

92 Park Street, Rutland, VT

Sealed Bid and M & E Online Auction Timelines

Sealed Bid Auction:

- Commencing: Monday, Feb. 16 @ 12PM (EST)

- Preview Date: Inspection by Appointment

- Auction Closes: Final Bids Due by Tuesday, March 3, 2026 @ 12PM (EST)

- Payments Due: Friday, March 6 @ 2PM (EST)

- Load Out Dates: Monday-Friday, March 9 - March 13 from 8AM-5PM (EST)

Machinery and Equipment Timed Online Auction (#1729):

- Auction Launch Date: Monday, March 9 @ 4PM (EST)

- Preview Date: Monday, March 23 from 10AM - 1PM (EST)

- Auction Closes: Tuesday, March 31 @ 10AM (EST)

- Load Out Dates: Monday-Friday, April 6 - 10 from 9AM-4PM (EST)

Timed Auction includes:

- Alloy Blister Packing Machines

- Robotic Polishers

- Material Handling & Warehouse Equipment

- Pallet Rack

- Large Dust Collection System

- Forklifts

- Rotary Scissor Lift Tables

- Pallet Scale and Wrapper

- Mixers and Pumps

- Air Compressors, incl. I.R. 75 HP Screw

- Rosler R550/4600DA & Sweco FM-100 Vibratory Finishing Machines

- Ovens

- Markem Inkjet Printers

Sealed Bid Instructions - Questech Corporation

Thank you for your interest in the SEALED BID AUCTION of part of Questech Corporation intellectual and personal property assets located at 92 Park St, Rutland, VT 05701. If you would like to submit a sealed bid, please follow these instructions to submit your bid to Thomas Hirchak Company no later than 12:00 PM EST Tuesday, March 3rd, 2026. Bids will be opened at 12:30 PM EST Tuesday, March 3rd, 2026. Thomas Hirchak Company, as the Seller's agent, and the Seller are not responsible for bids that do not arrive prior to bid closing. All bids are subject to the Seller's approval. Seller reserves the right to reject any and all bids.

- Please read and familiarize yourself with bidding process outlined within the Information Memorandum and Sealed Bid Procedure.

- Bidders will be required to deposit a $10,000 USD deposit in the form of wire or bank check for each individual bid with Thomas Hirchak Company, acting as Escrow Agent on behalf of client. Deposits must be received within 24 hours of bid acceptance notification. Contact auctioneers office at 802-888-4662 or questech@thcauction.com for wire instructions.

- Appointments may be made through THOMAS HIRCHAK COMPANY for qualified bidders to gain access to Questech Corporation physical site/facilities between Wednesday, February 11th, 2026, and Monday, March 2nd, 2026 for the purpose of inspection.

- Complete the Sealed Bid Form. Please fill in the maximum amount of your bid(s), sign and date the Sealed Bid form.

- Email the completed Sealed Bid form in PDF format to: questech@thcauction.com.

Or mail completed Sealed Bid Form document to:

Thomas Hirchak Company

1878 Cadys Falls Rd

Morrisville, VT 05661

Attn: Questech Corporation Auction

- Lab Equipment

- Woodworking Machinery

- Pressure Pots

- Stationary Sanding Machines

- Wet Tile / Masonry Saws

- Powder Sieves

- Flammable Material Cabinets

- CNC Routers

- Rubber Mold Making Equipment

- Maintenance Shop

- Offices

- Finished Product

- More…

Sealed Bid Procedure - Questech Corporation

- Bidder downloads Information Memorandum (IM), Sealed Bid Form & Purchase and Sale agreement (P&S).

- Bidder returns Sealed Bid Form and $10,000 USD deposit (per lot) in the form of a wire or bank check to Thomas Hirchak Company.

- Sealed Bids delivered to Thomas Hirchak Company by 12:00 PM EST Tuesday, March 3rd, 2026.

- Deposit Funds verified by authorized Thomas Hirchak Company as Agent for Seller.

- Sealed Bids opened by authorized Thomas Hirchak Company as Agent at 12:30 PM EST Tuesday, March 3rd, 2026.

- Winning Bidder(s) notified by a Thomas Hirchak Company as Agent at 1:00 PM EST Tuesday, March 3rd, 2026.

- Winning Bidder(s) return executed Purchase & Sale Agreement.

- Under Bidder / Non-Bidder deposits returned 2nd business day following opening of bids.

- Winning Bidder(s) closes sale on or before 2:00 PM EST, Thursday, March 5th, 2026.

- All won lots must be removed between Monday, March 9th, 2026 and Friday, March 13th, 2026.

Specifications are not guaranteed, incl.: electric phase, volts and amperage; speeds; dimensions; temperature ranges; weights; capacities; patent and trademark numbers & status.

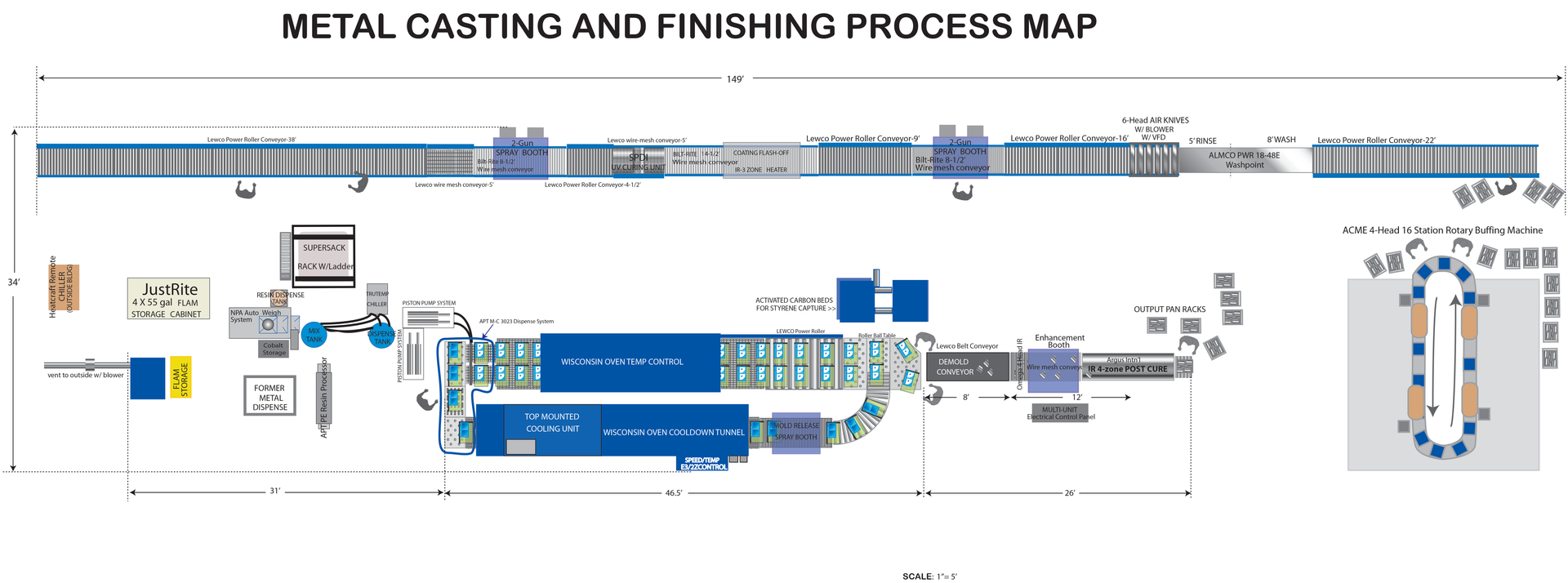

Lot 1

Semi-Automated Cast Resin "Metal" Production Line

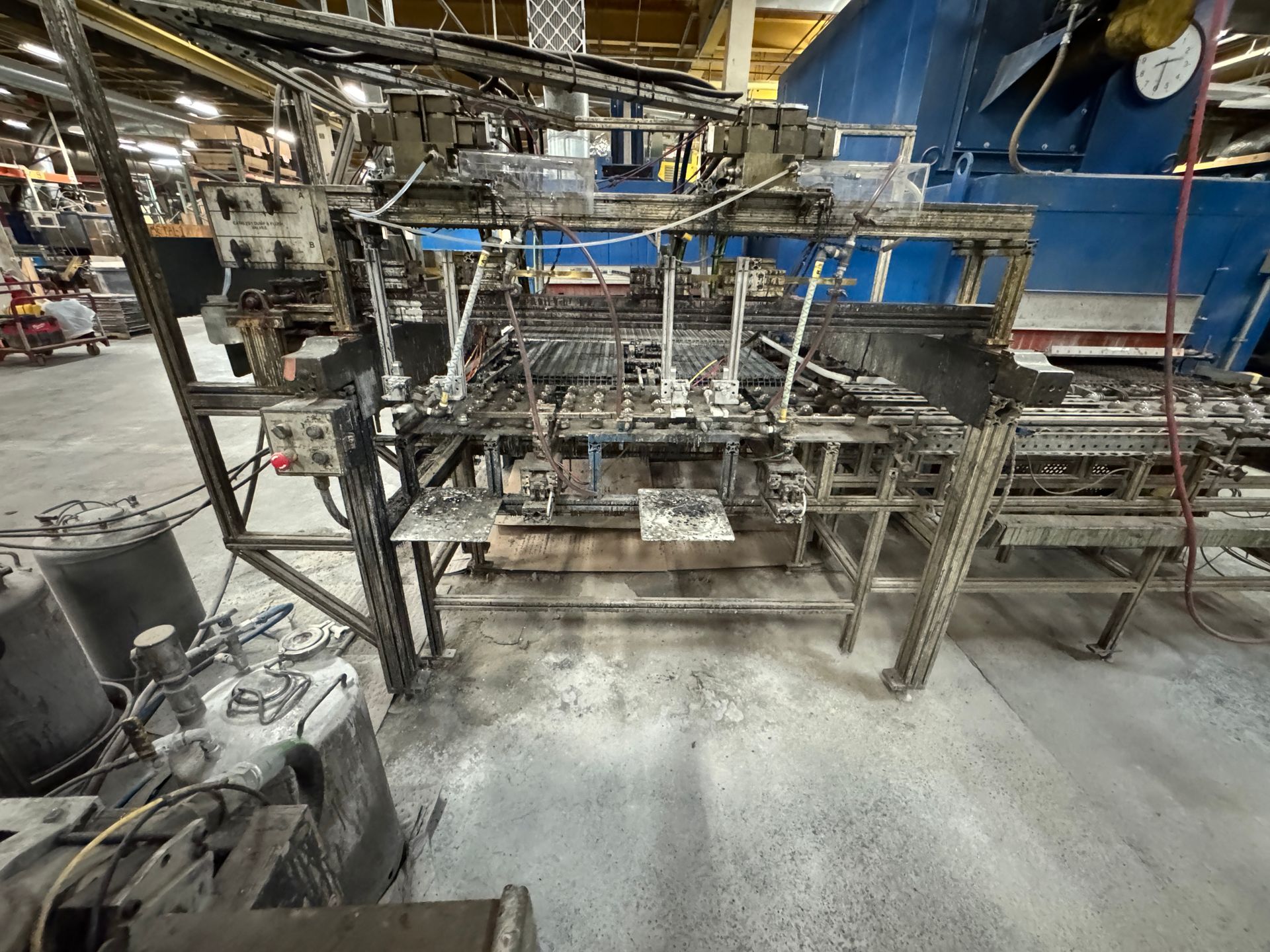

Complete operating line to produce metal finish cast resin products, most recently being tiles and small bathroom fixtures, comprised of:

- JustRite 4x55 gallon Outdoor Rated Flammables Cabinet

- Flammables Storage Cabinet; 24" x 48" x 31"

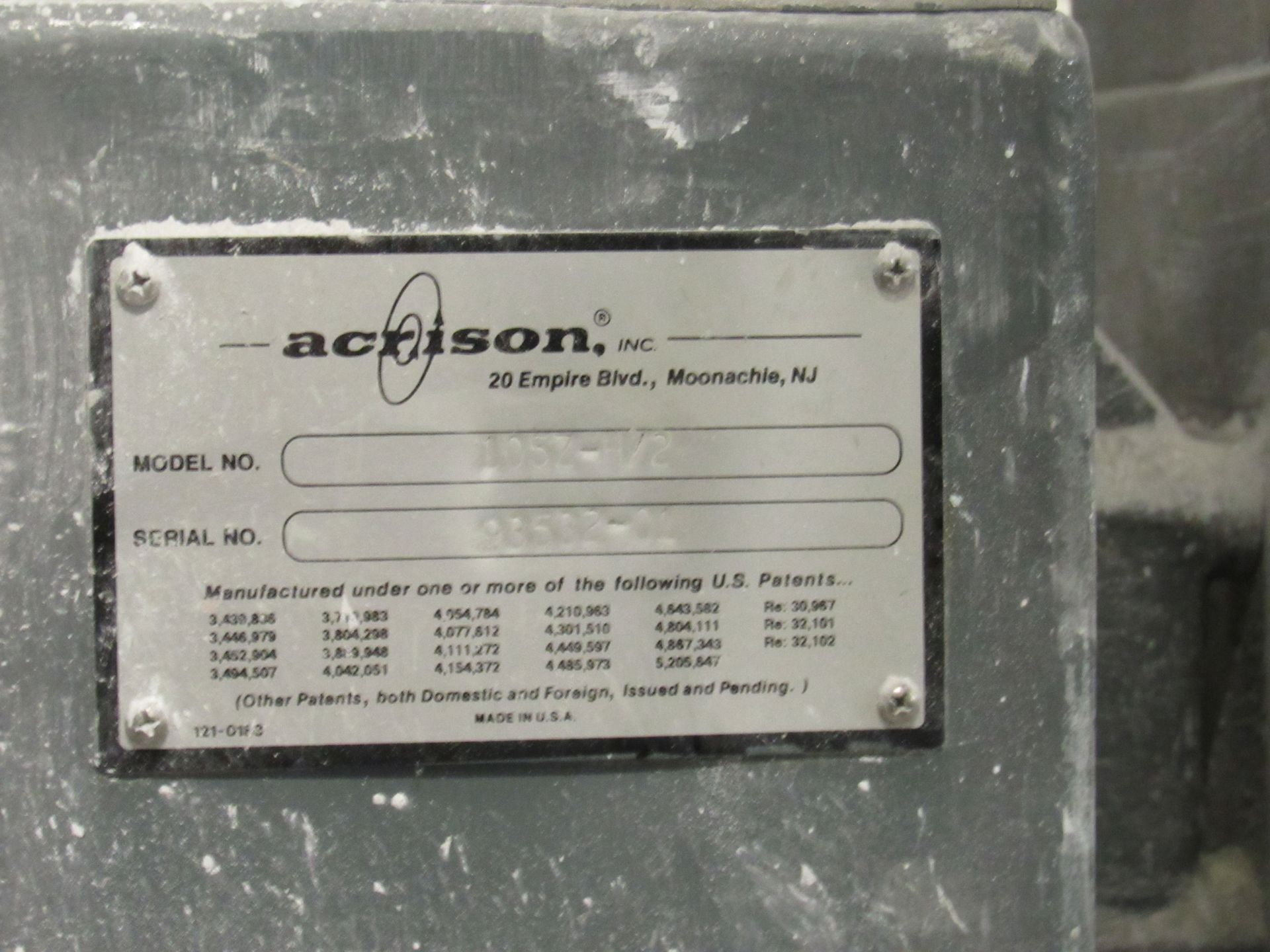

- NPA Automated Super Sack Weigh System; s.n. 10550; 480V; 3 PH; lacking the load cells

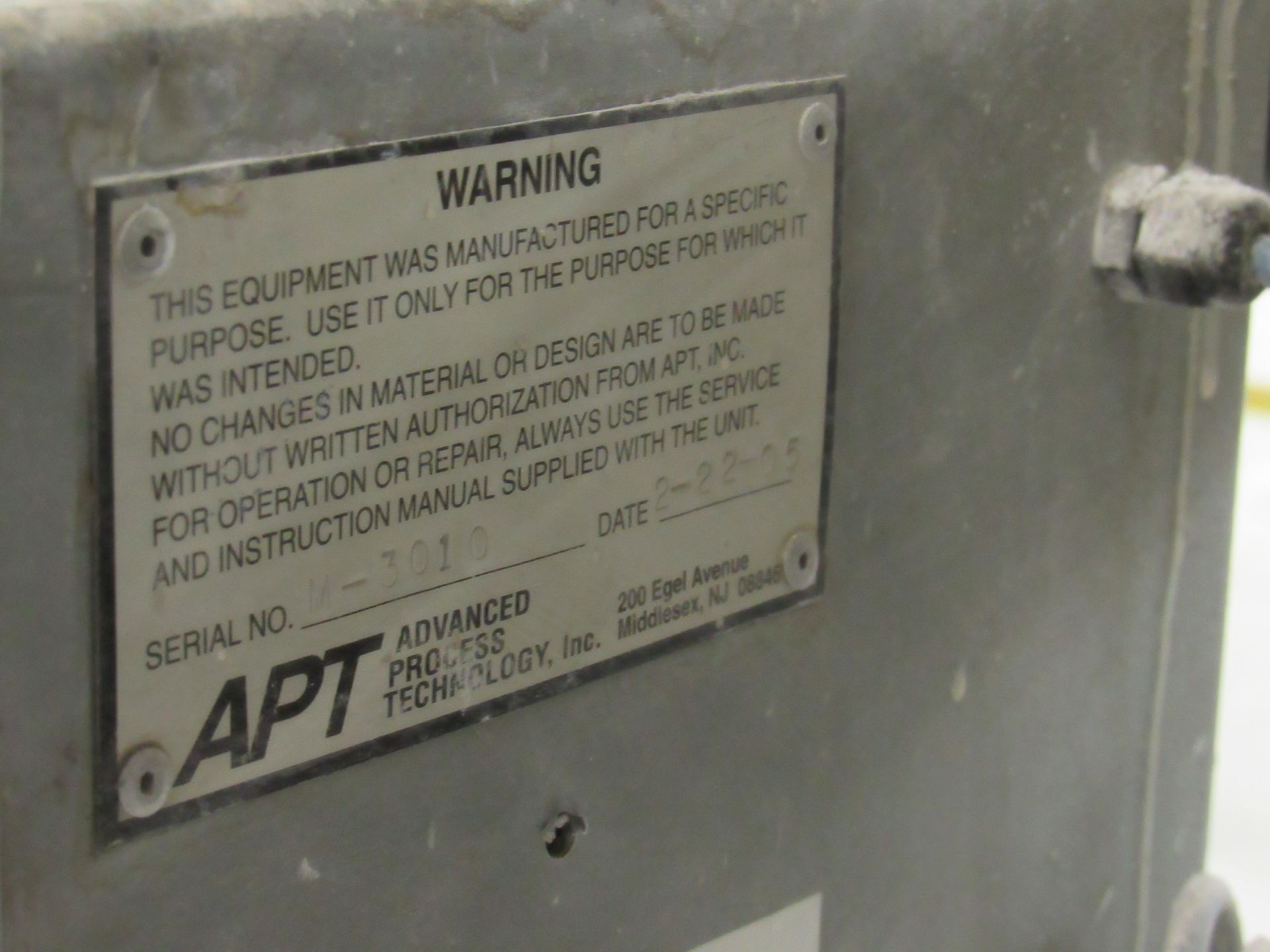

- Advanced Process Technology ECS Series Polyester Resin Processor; s.n. EC3007; 240V, 3 PH

- Steel Super Sack Rack with integrated ladder

- Cobalt Cabinet

- Triple Pneumatic Vibratory Hoppers, Piab Vacuum Pump & Resin Tank on steel rack

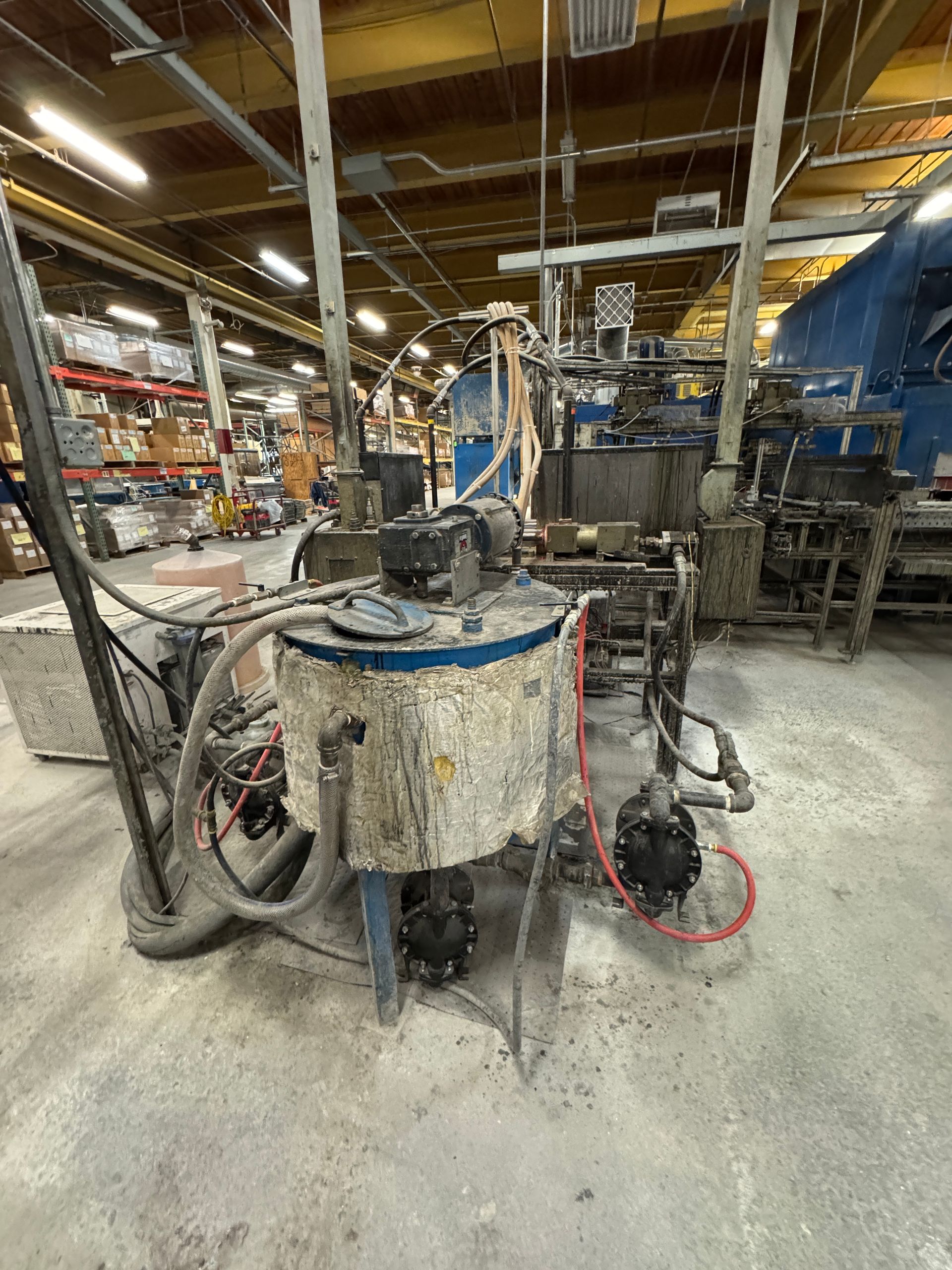

- 400# Jacketed Primary Mix Tank

- 400# Jacketed Dispensing Tank

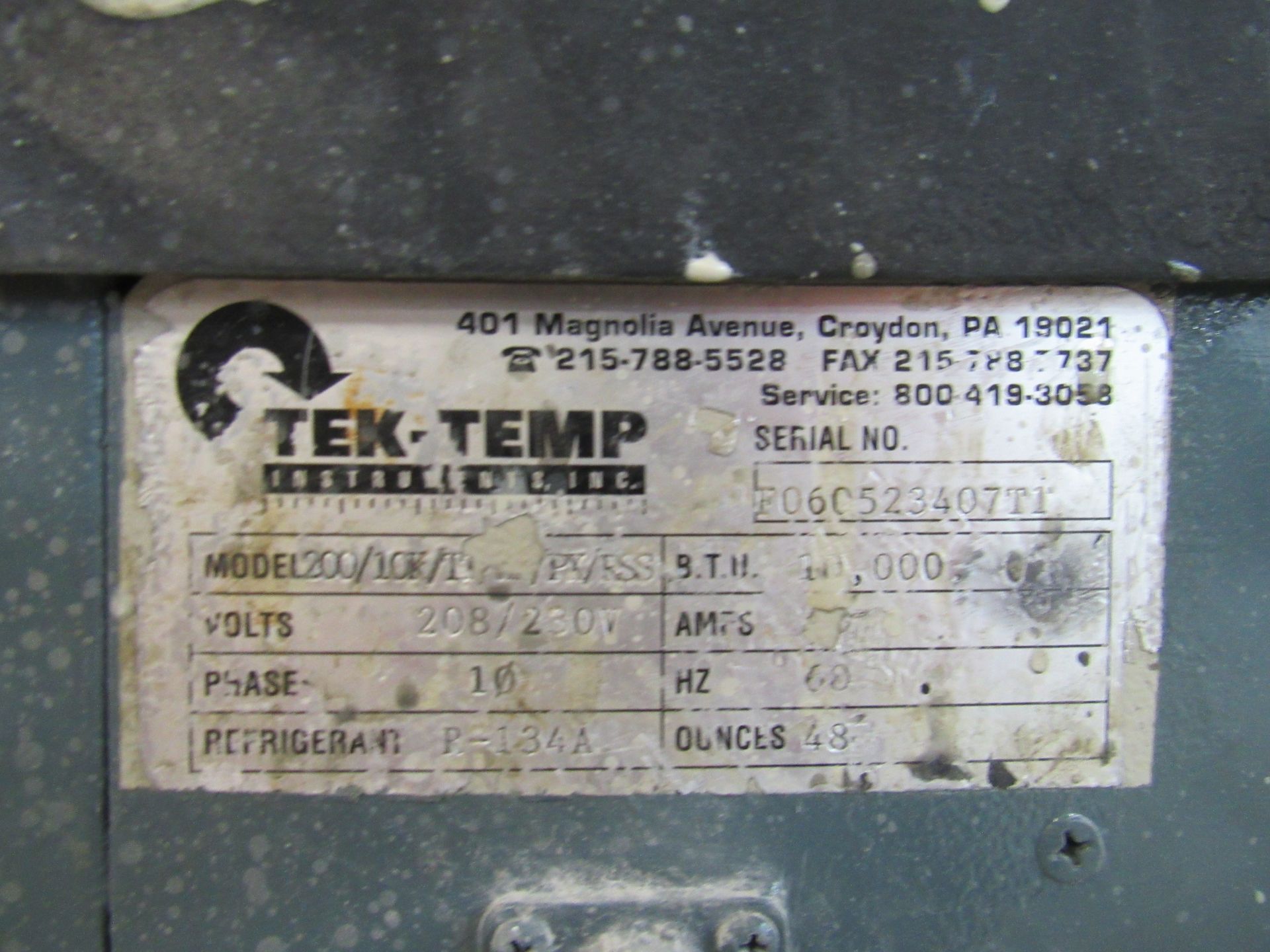

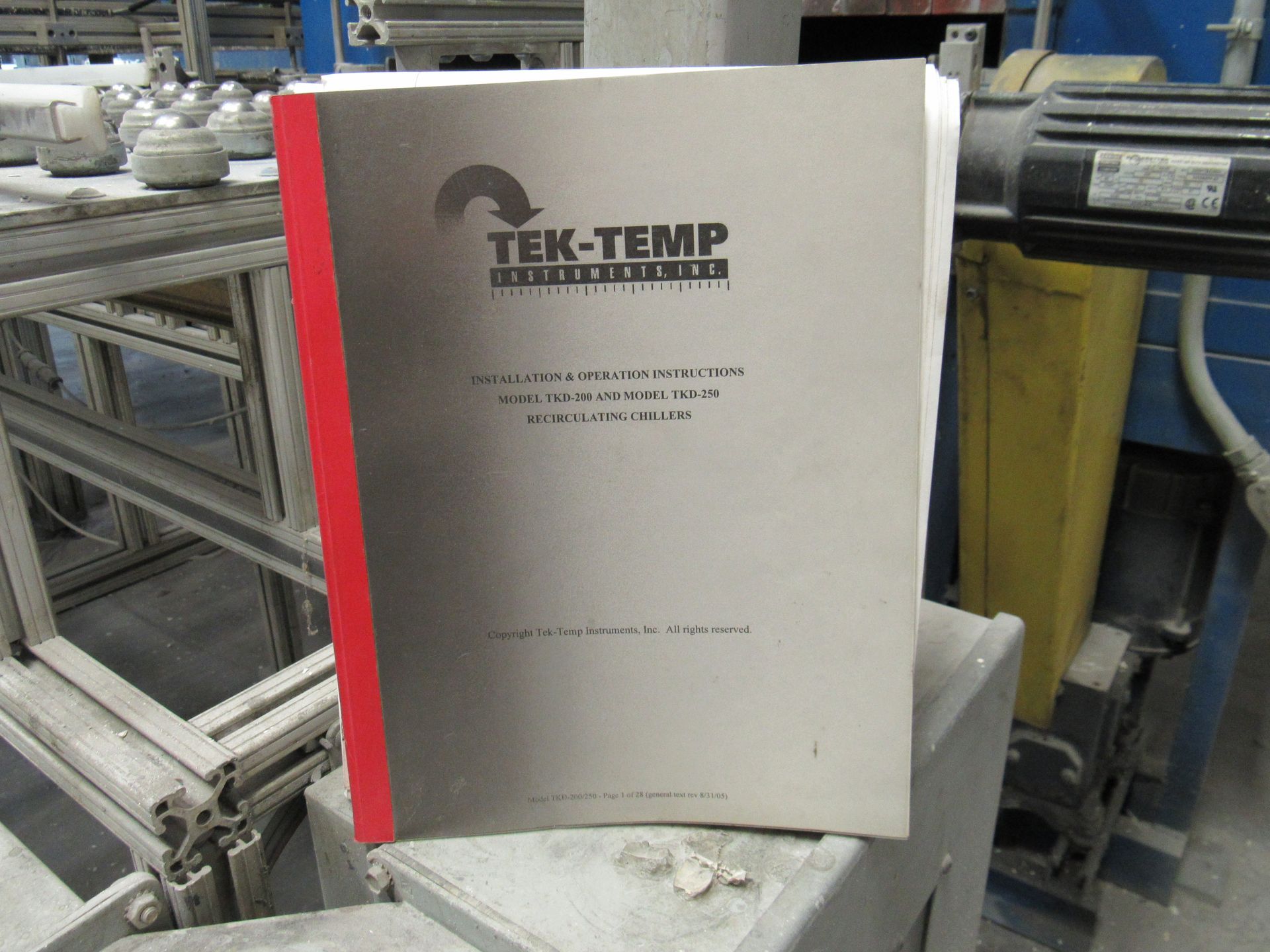

- TruTemp 200/10K BTU Chiller, 208V, 1 PH

- (2) APT SPPM-3025 Dual Piston Pumps

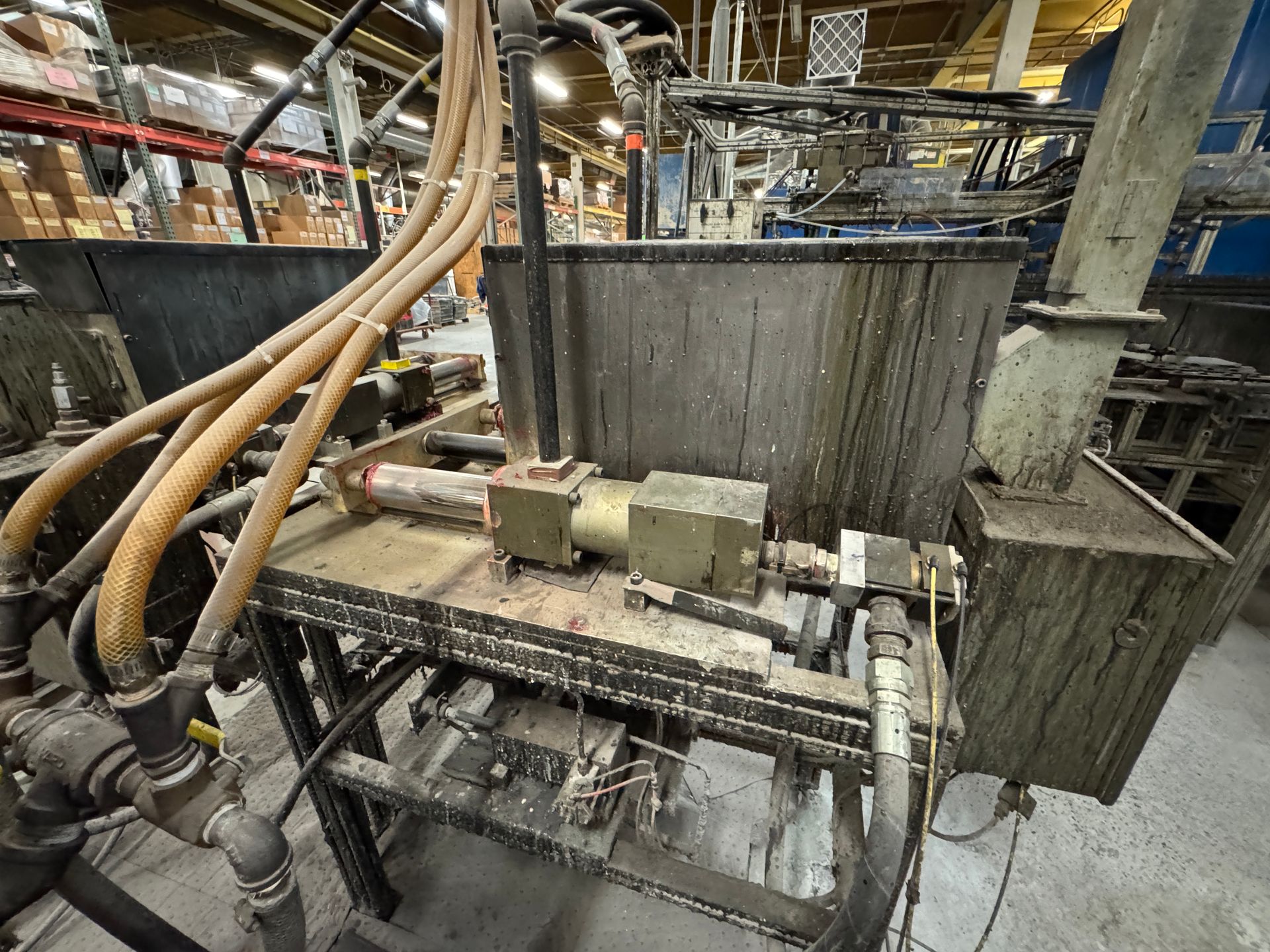

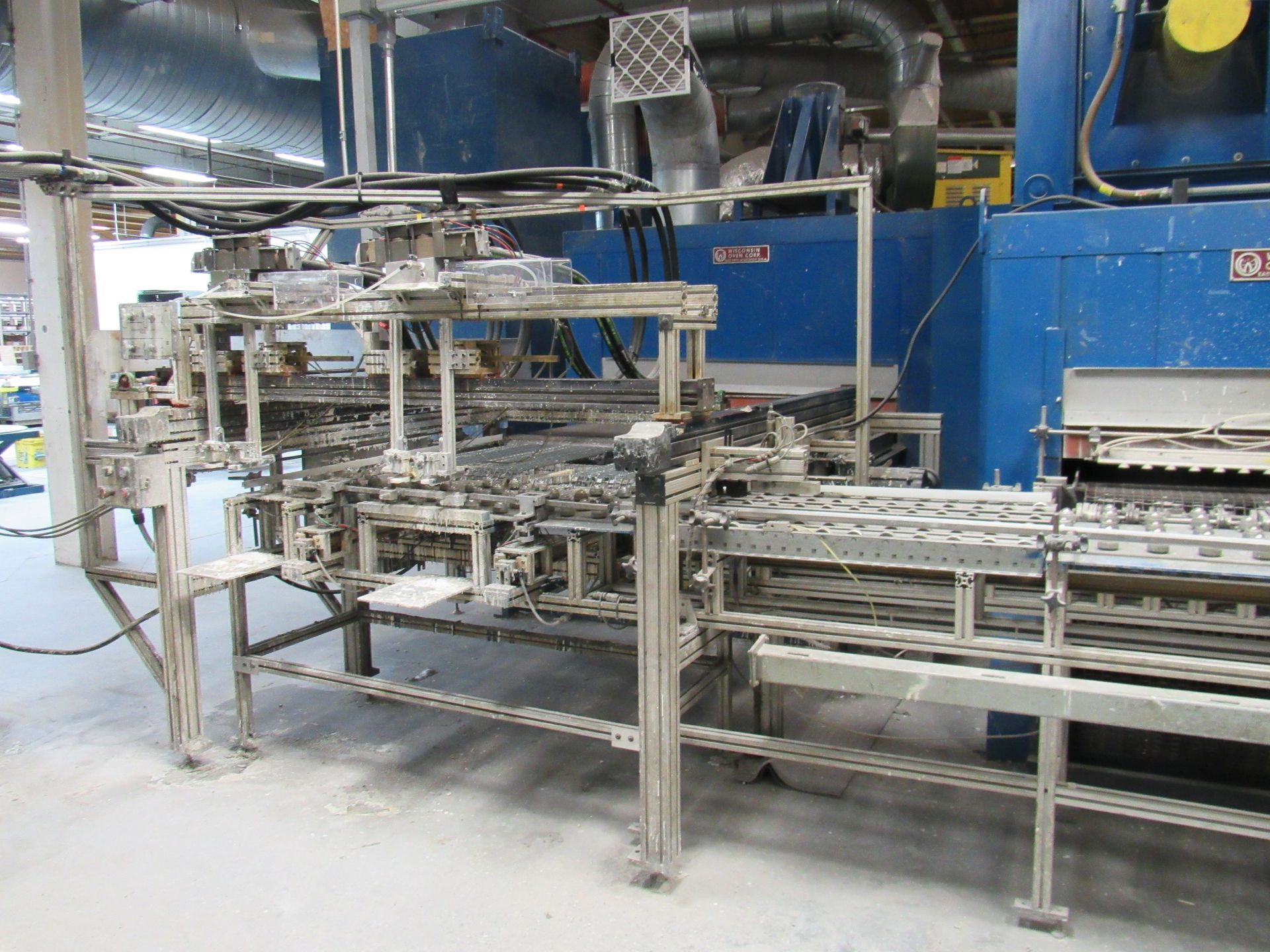

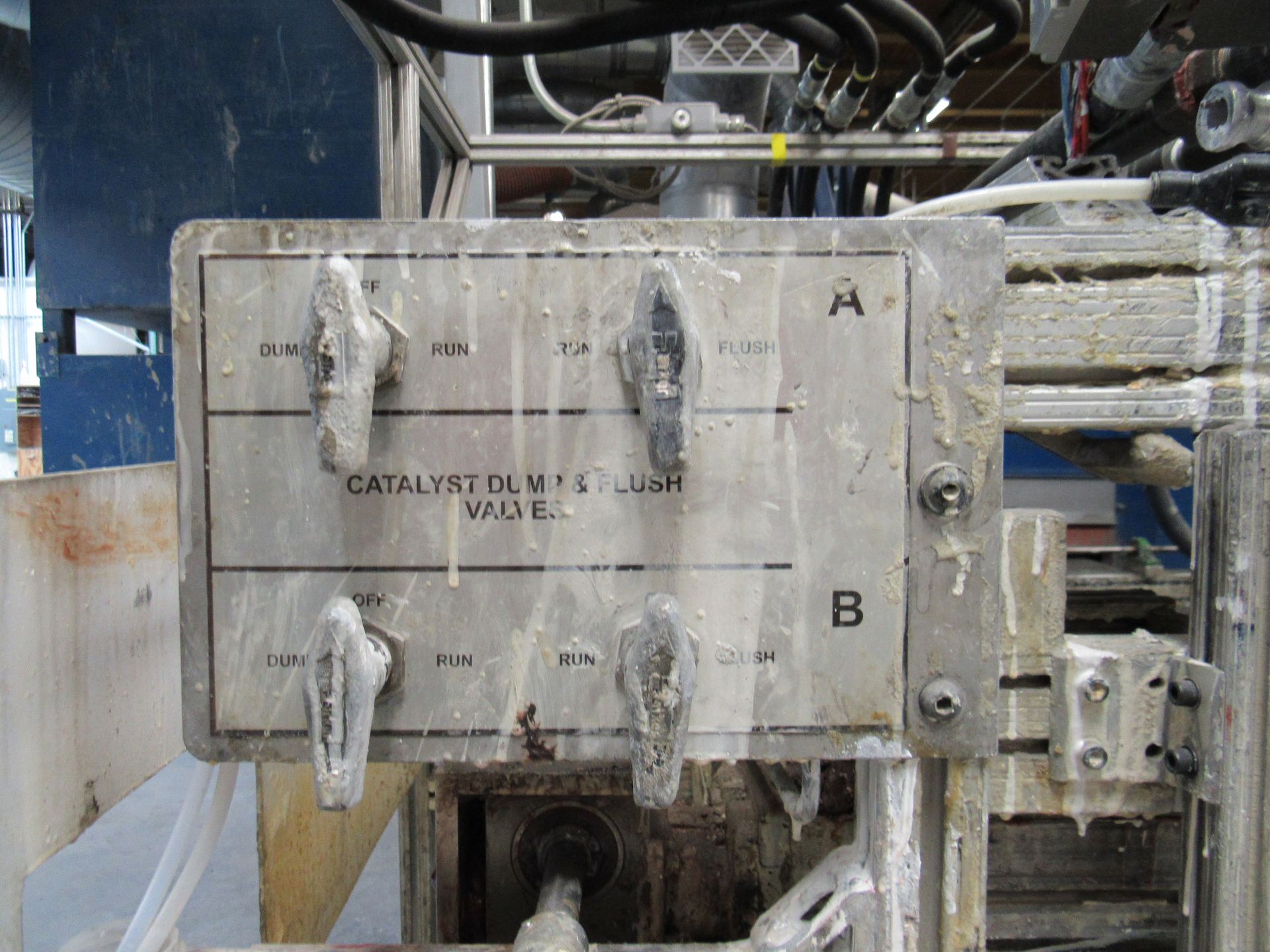

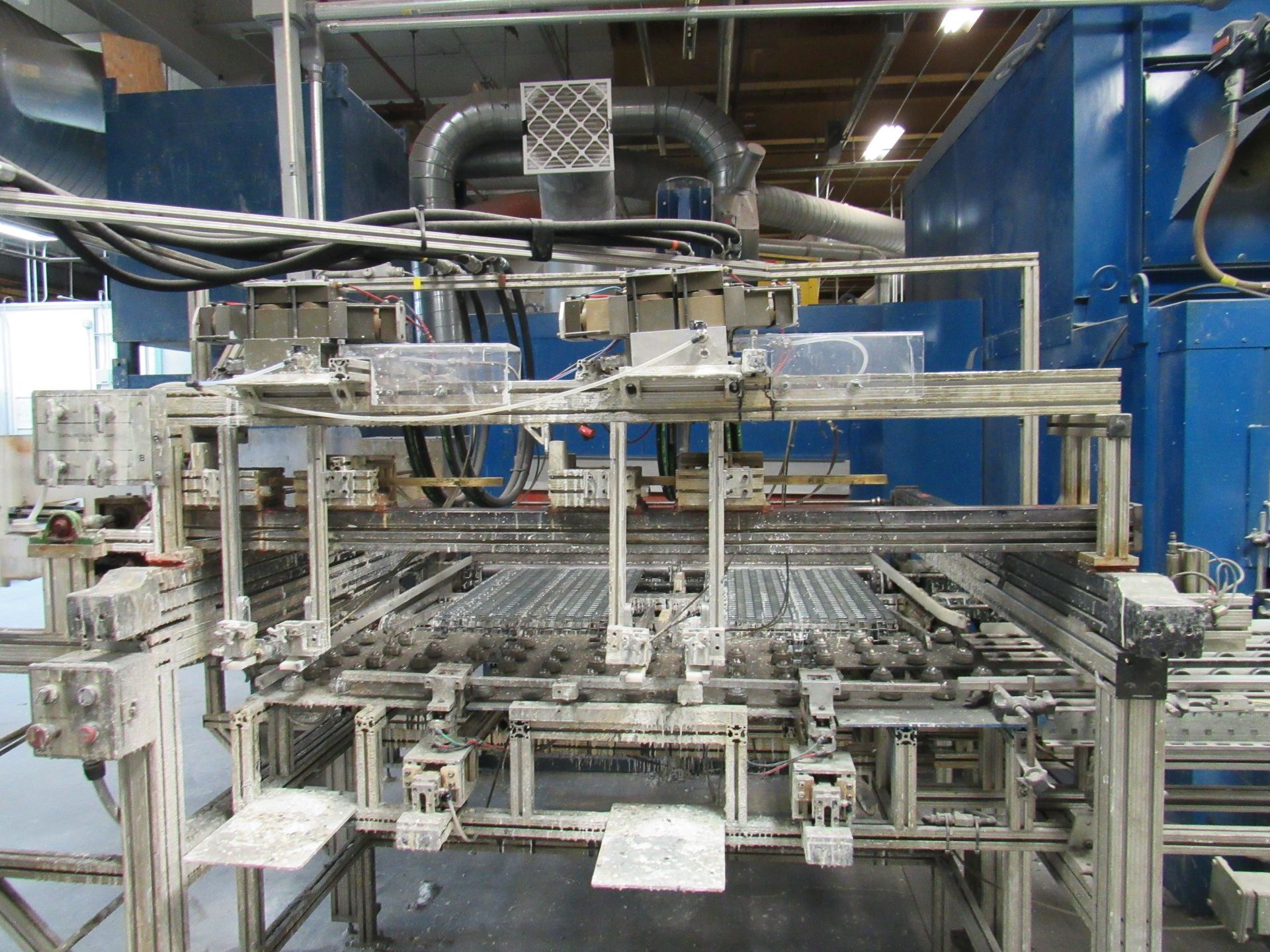

- APT M-C 3023 Dispensing System on dual head 3 axis gantry with static mixers and binary code mold reader (with option for continuous movement or lockdown dependent on mold volume)

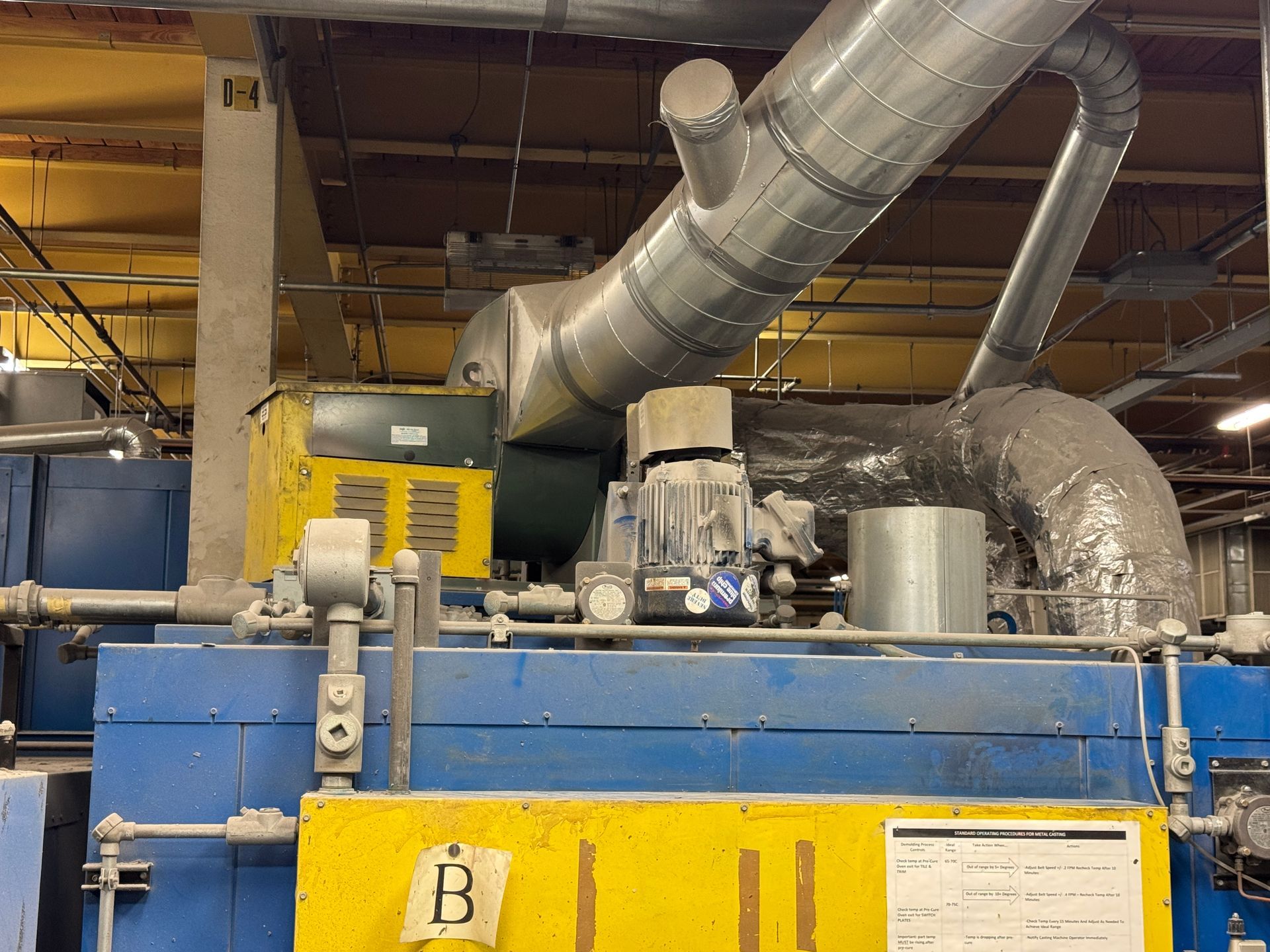

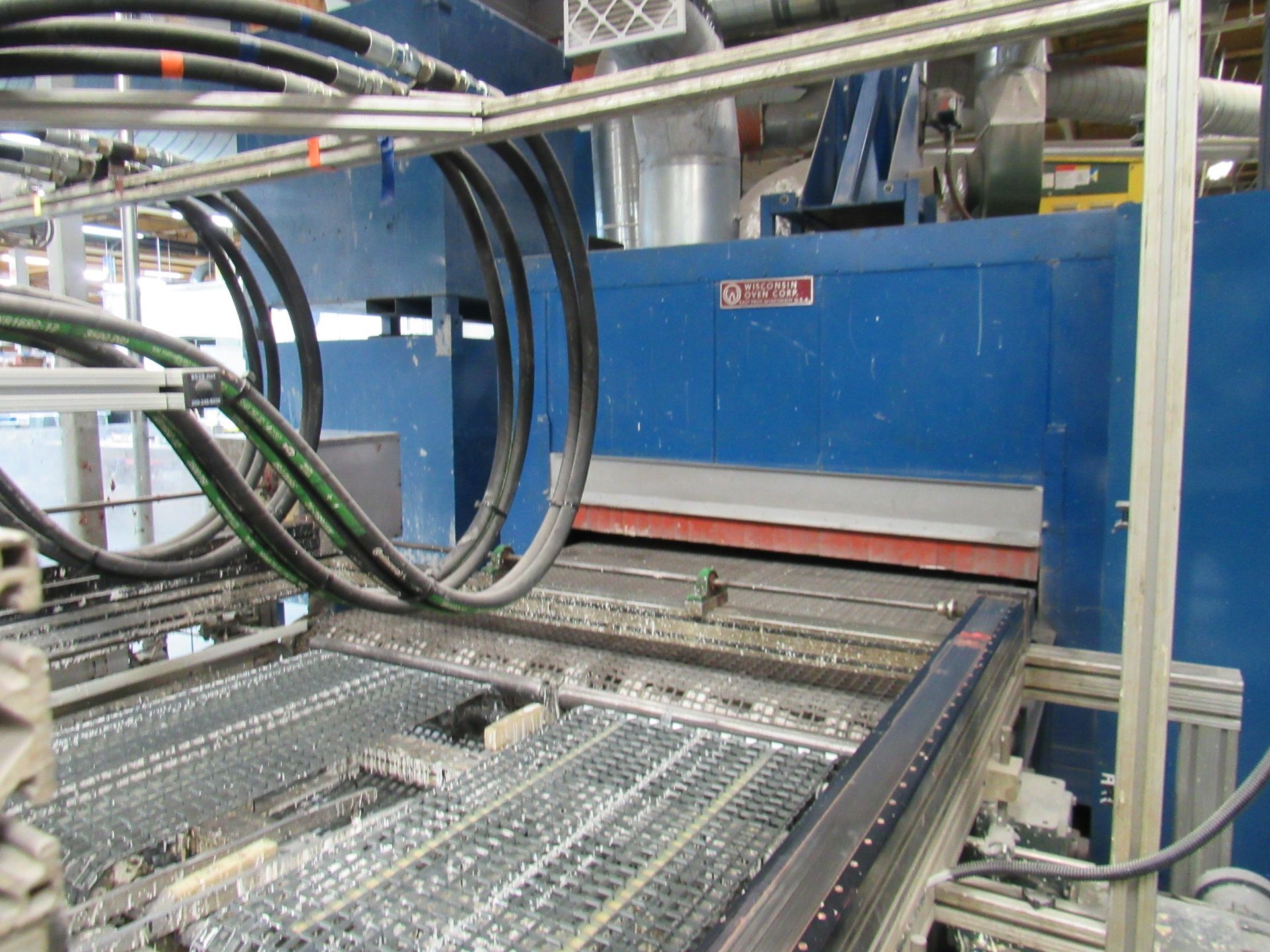

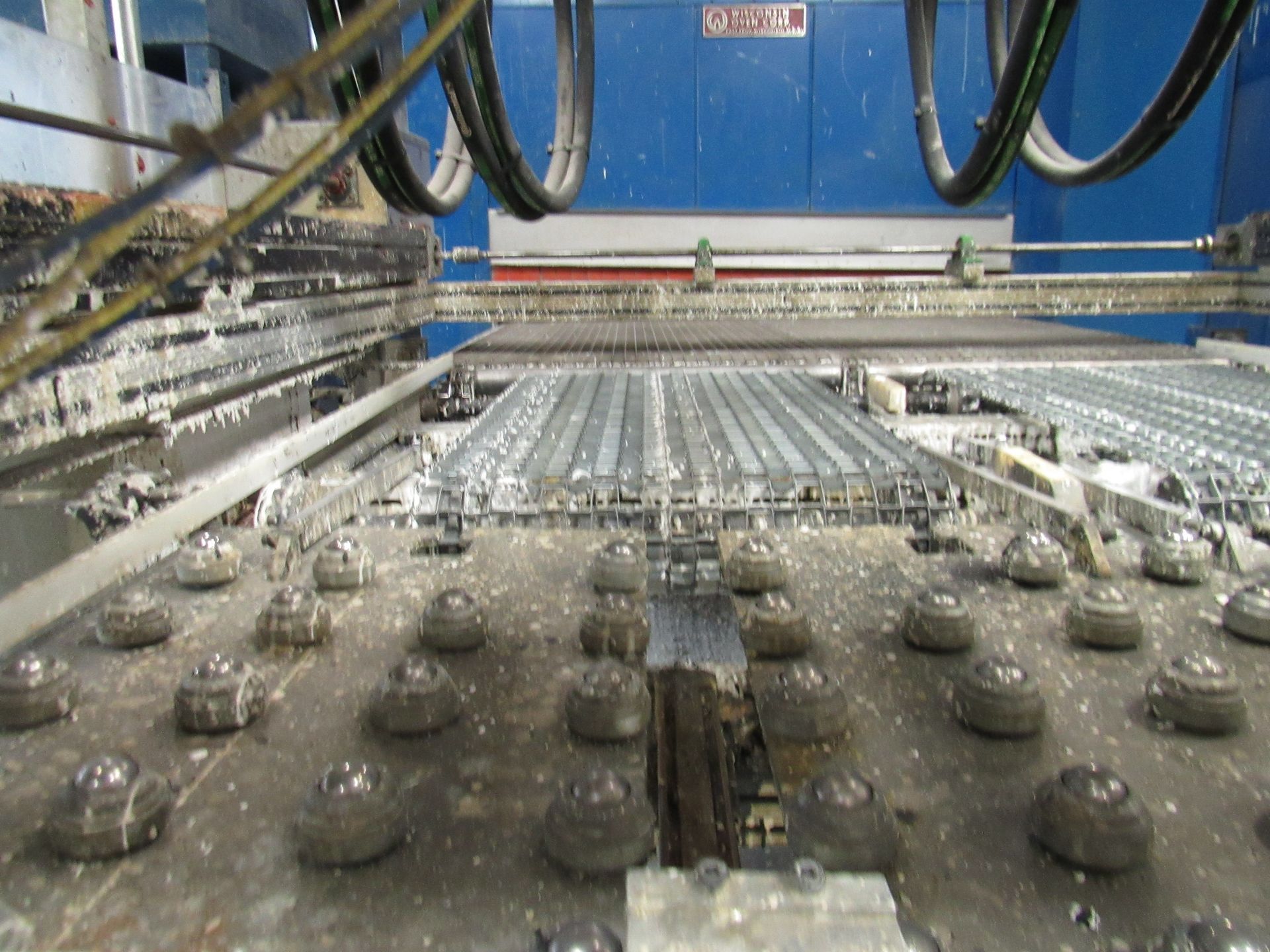

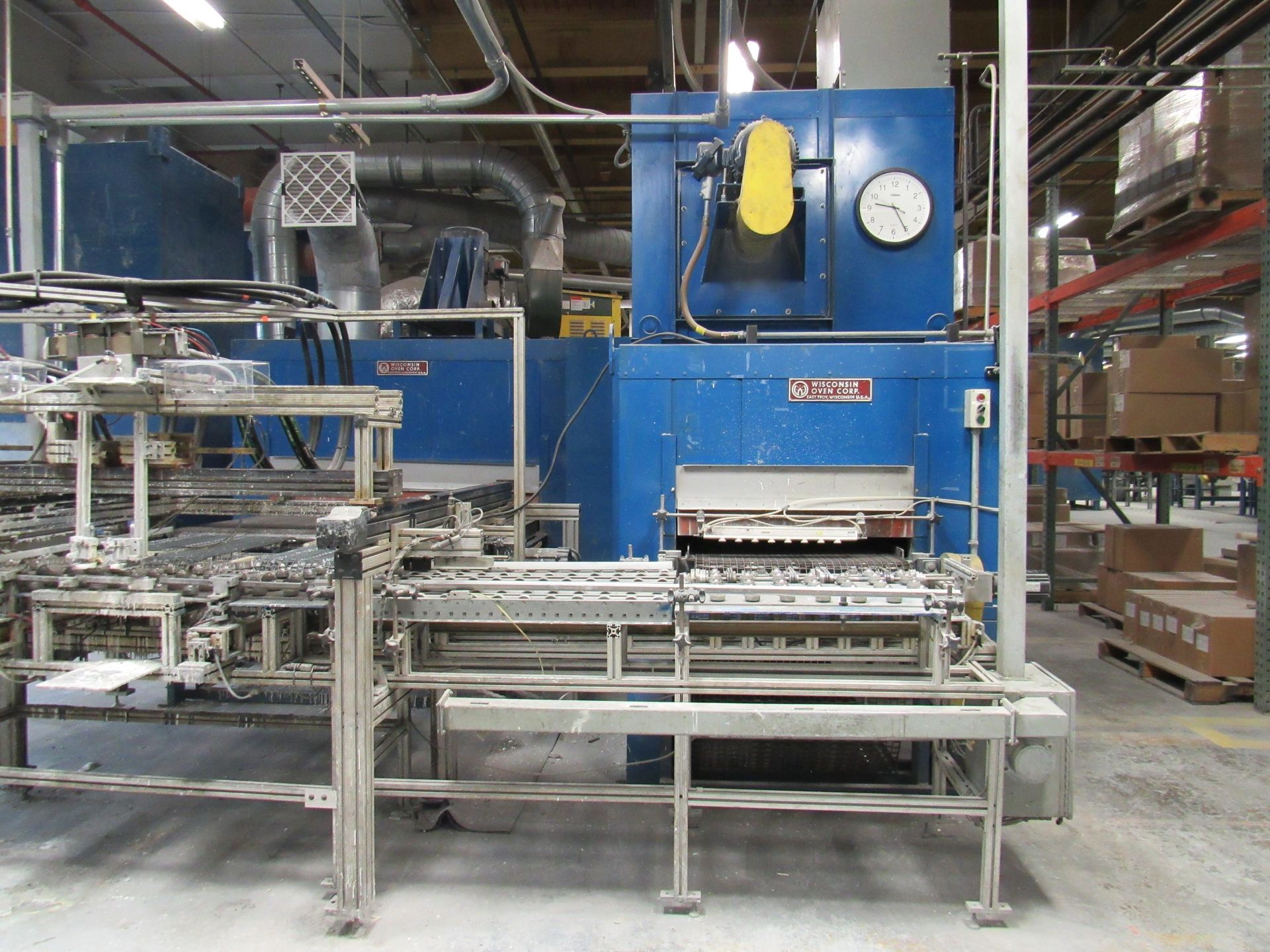

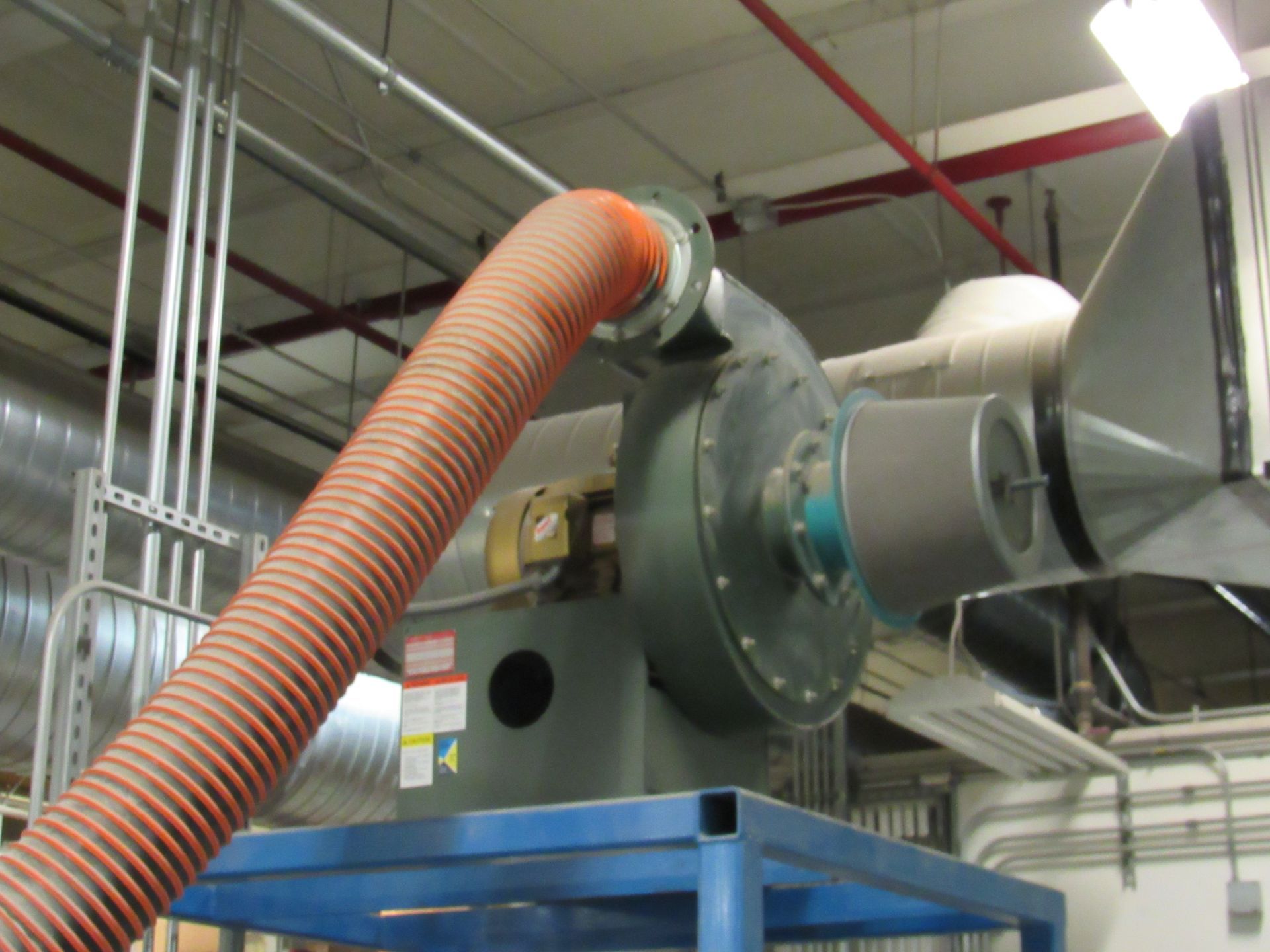

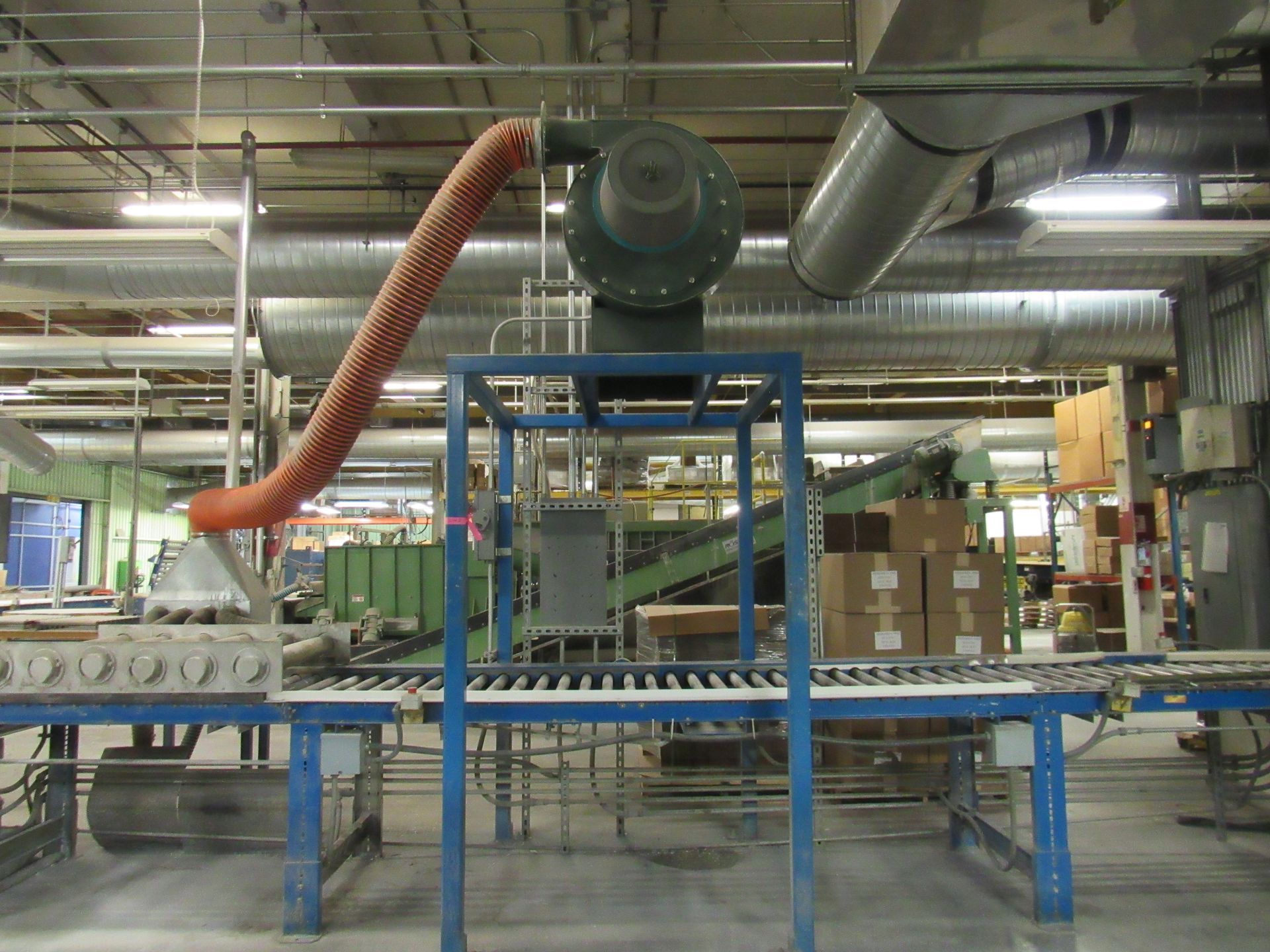

- Wisconsin Conveyor Oven; 5' x 26' wire mesh belt; 480V; 3 PH; 1.9-2.35 fpm belt speed; 300° F max temp; with blower

- (4) Activated Charcoal Carbon Beds for styrene removal

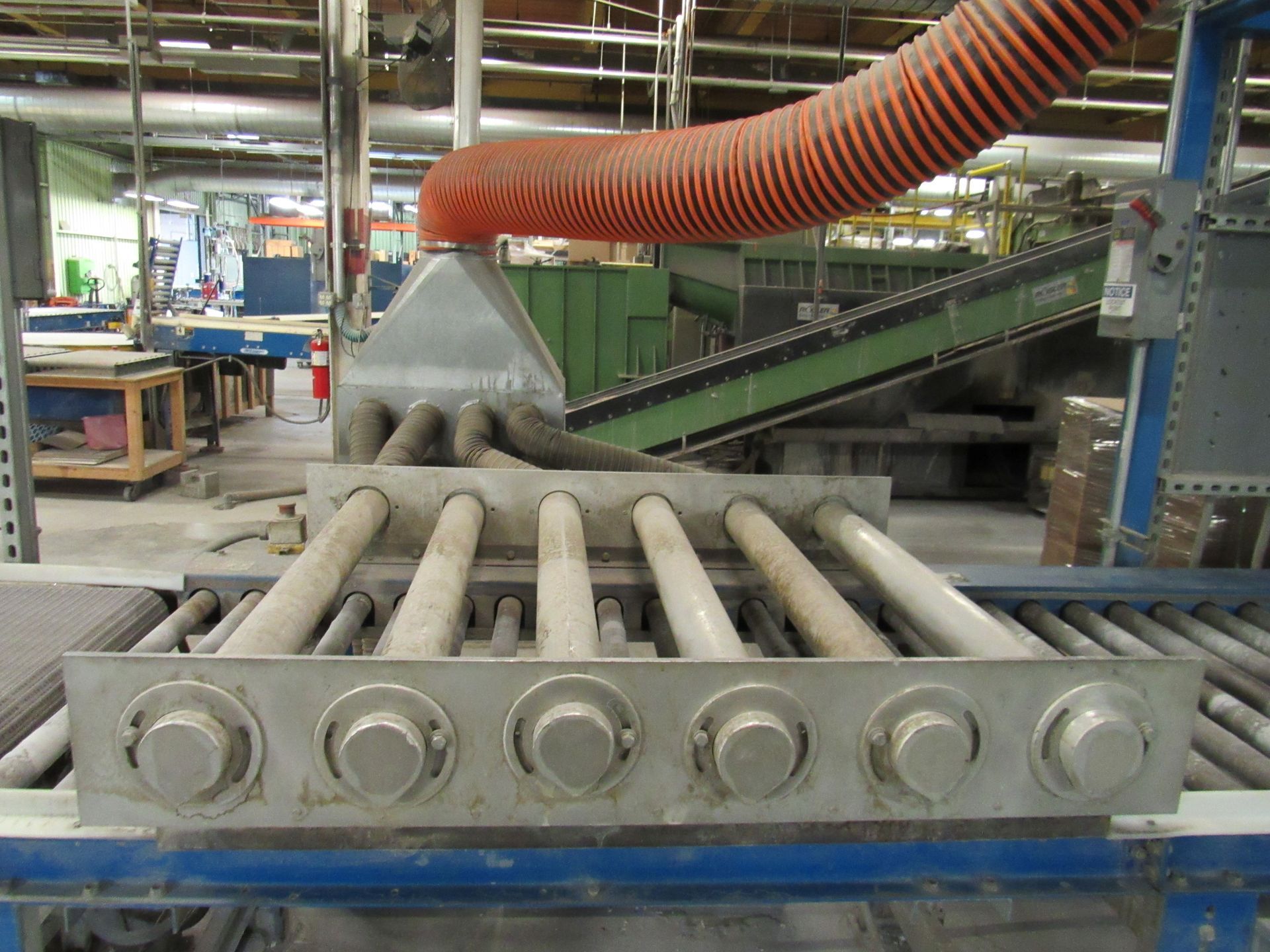

- Lewco 5' x 5' Power Roller Conveyor; 208-230/460V; 3 PH

- Roller Ball Table; 30" x 64" (where product is removed from molds)

- Power Roller Conveyor; 30" x 6'; 208-230/460V; 3 PH (molds back to chiller )

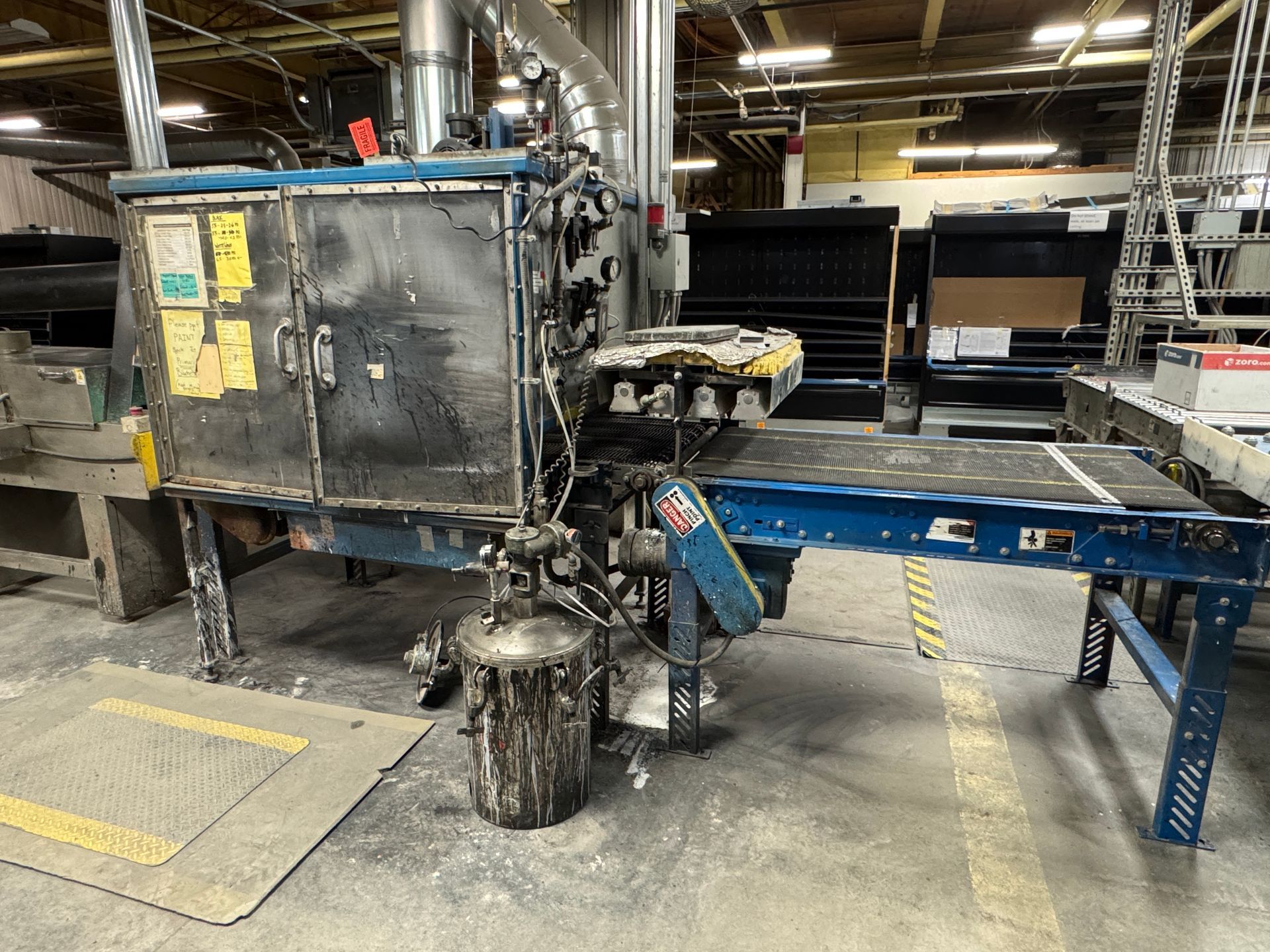

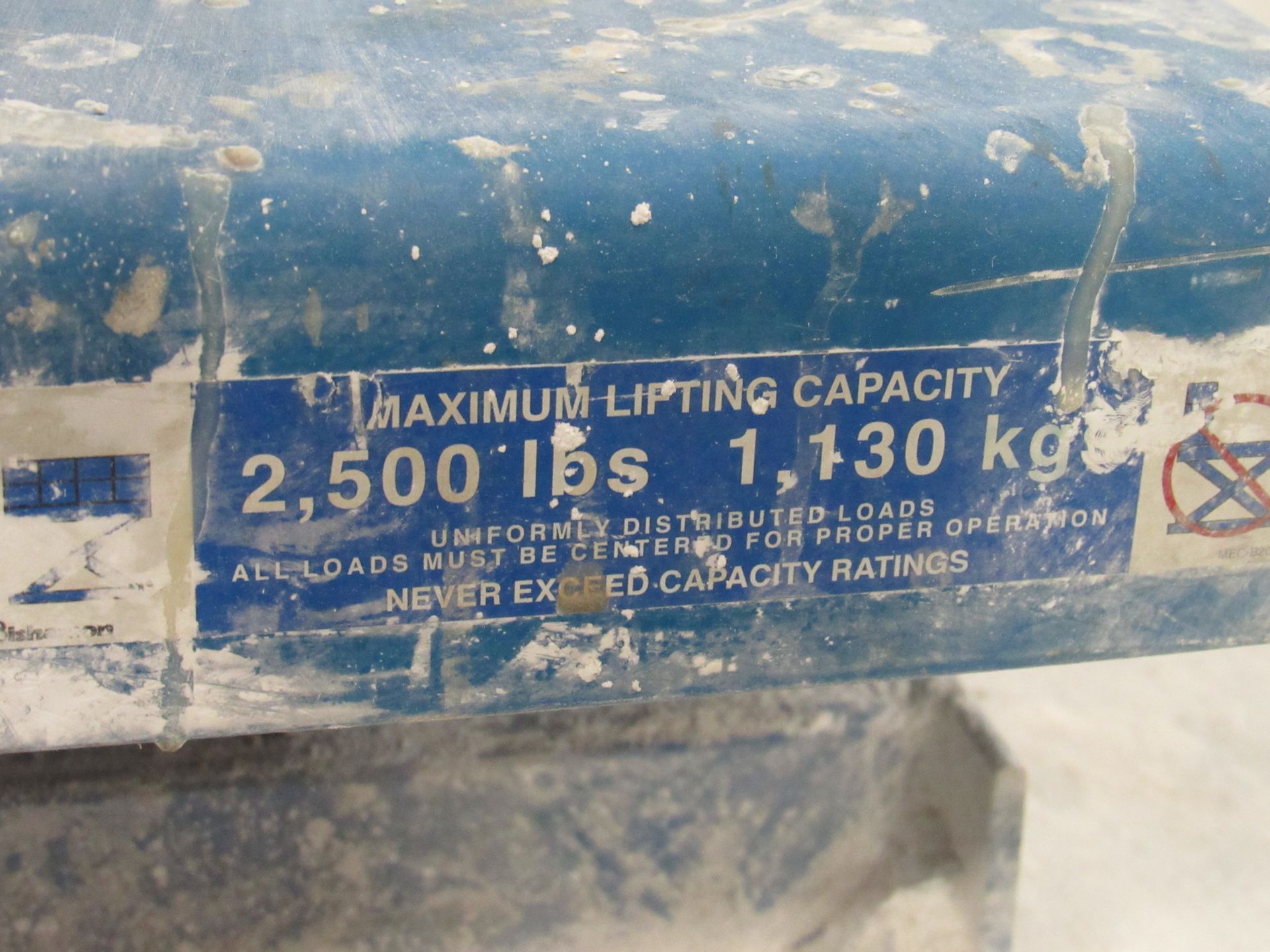

- Single Head Fully Traversing Gantry Spray Booth with regulator; over Bilt-Rite 30" x 7' wire conveyor; 208-230/460V; 3 PH

- Wisconsin Conveyor Chiller with air knife; 30" x 28' wire mesh belt; 7 fpm max. speed (to bring molds down to fillable temperature and conveyance back to filling station)

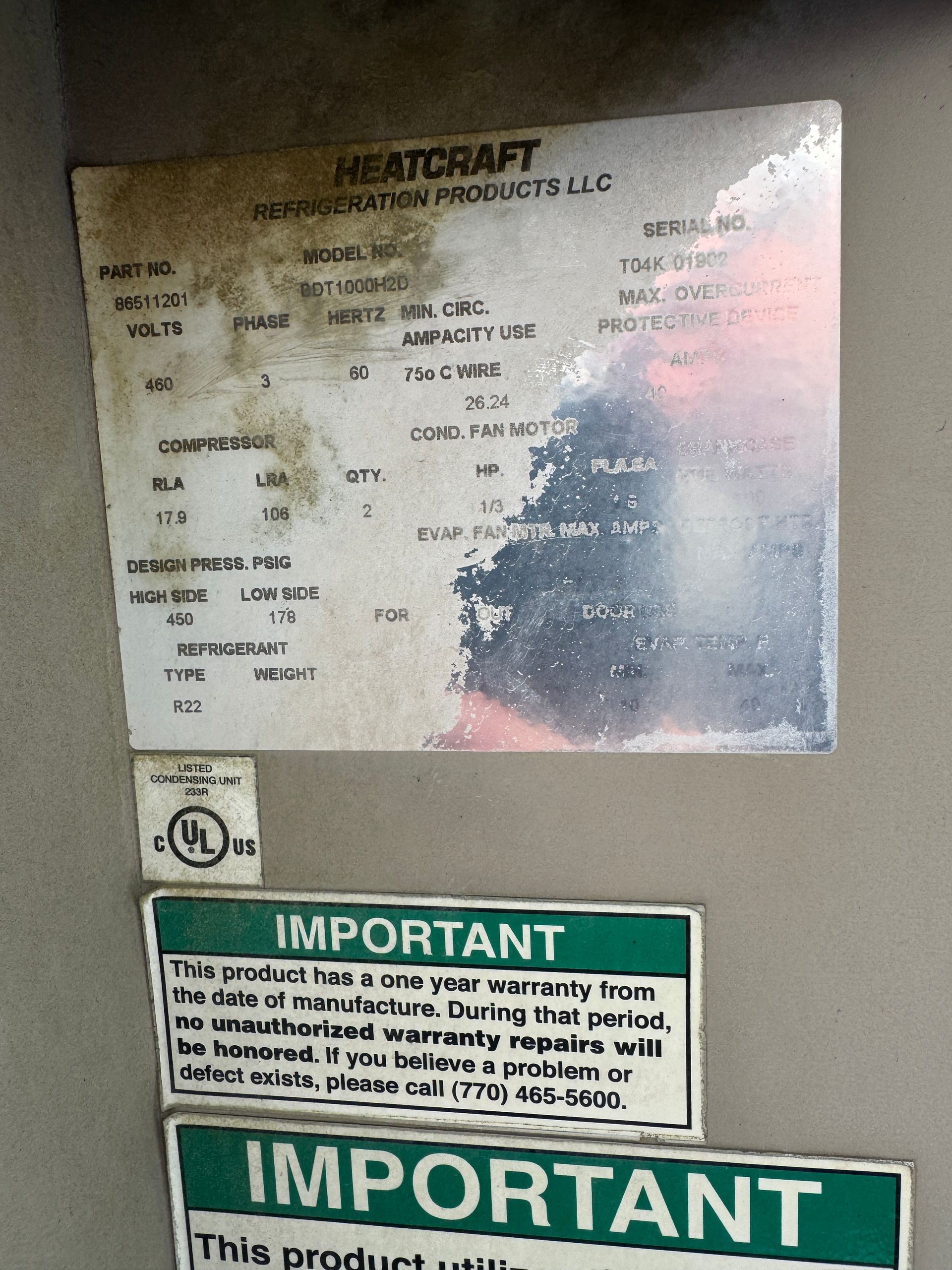

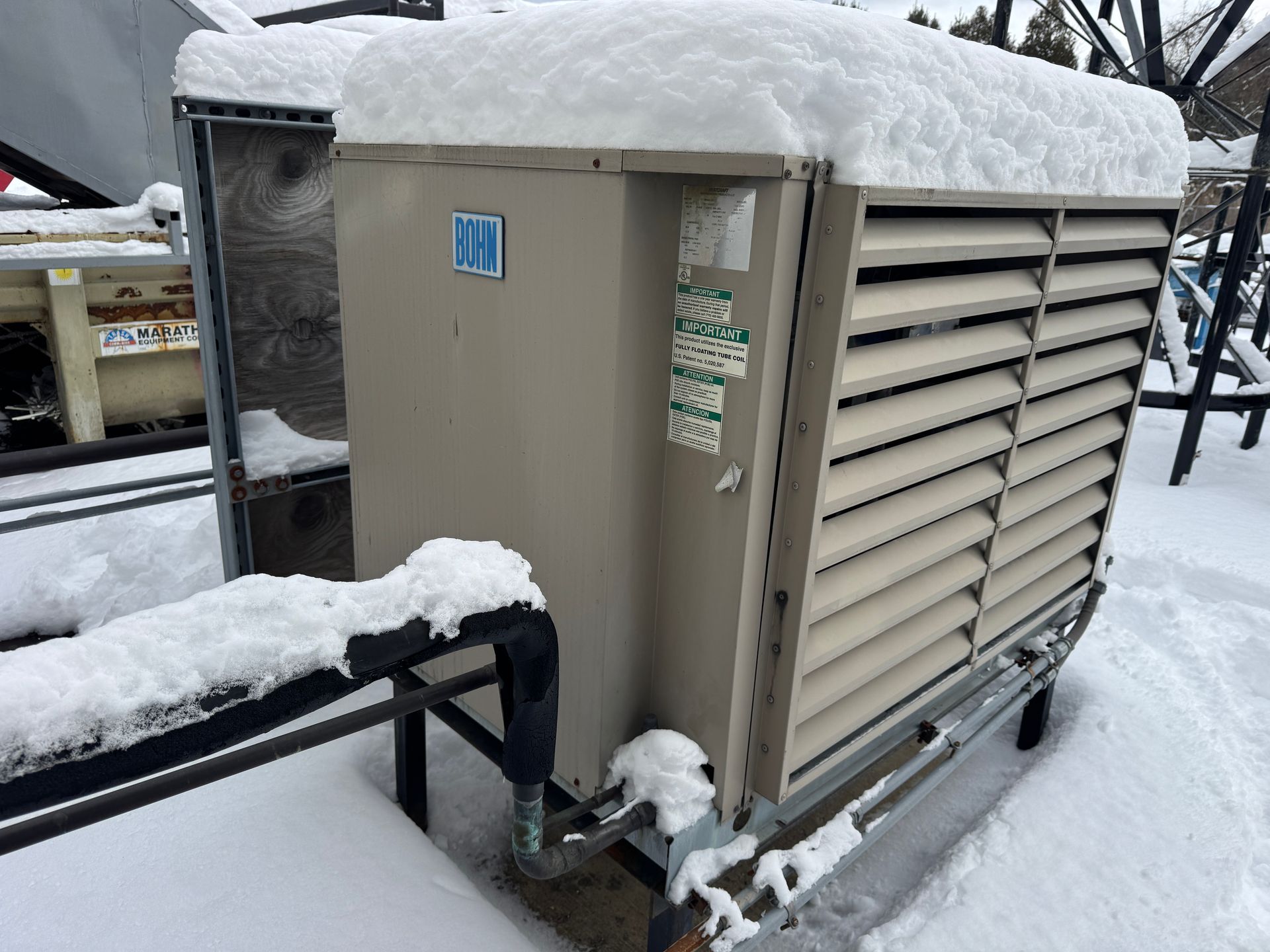

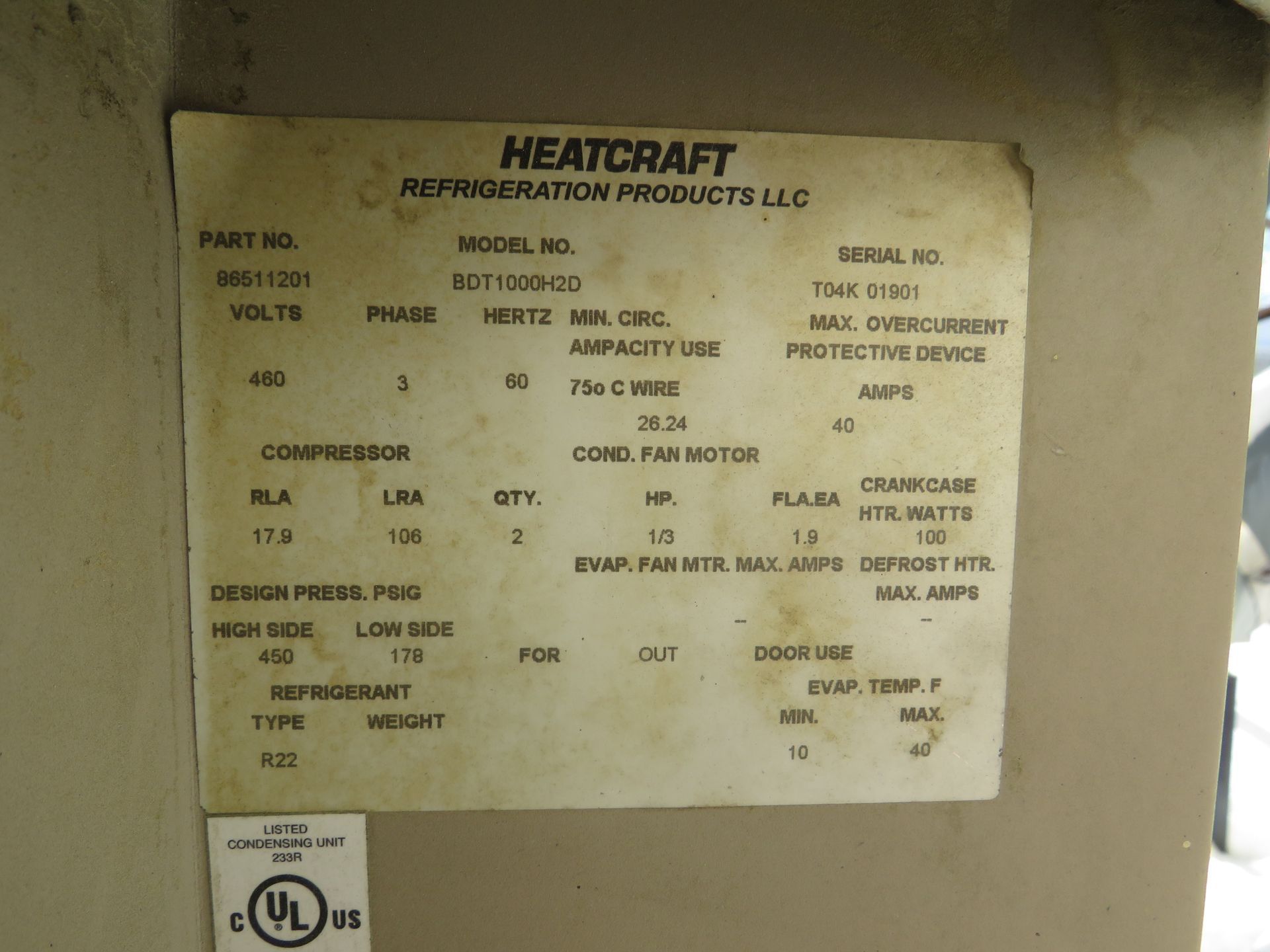

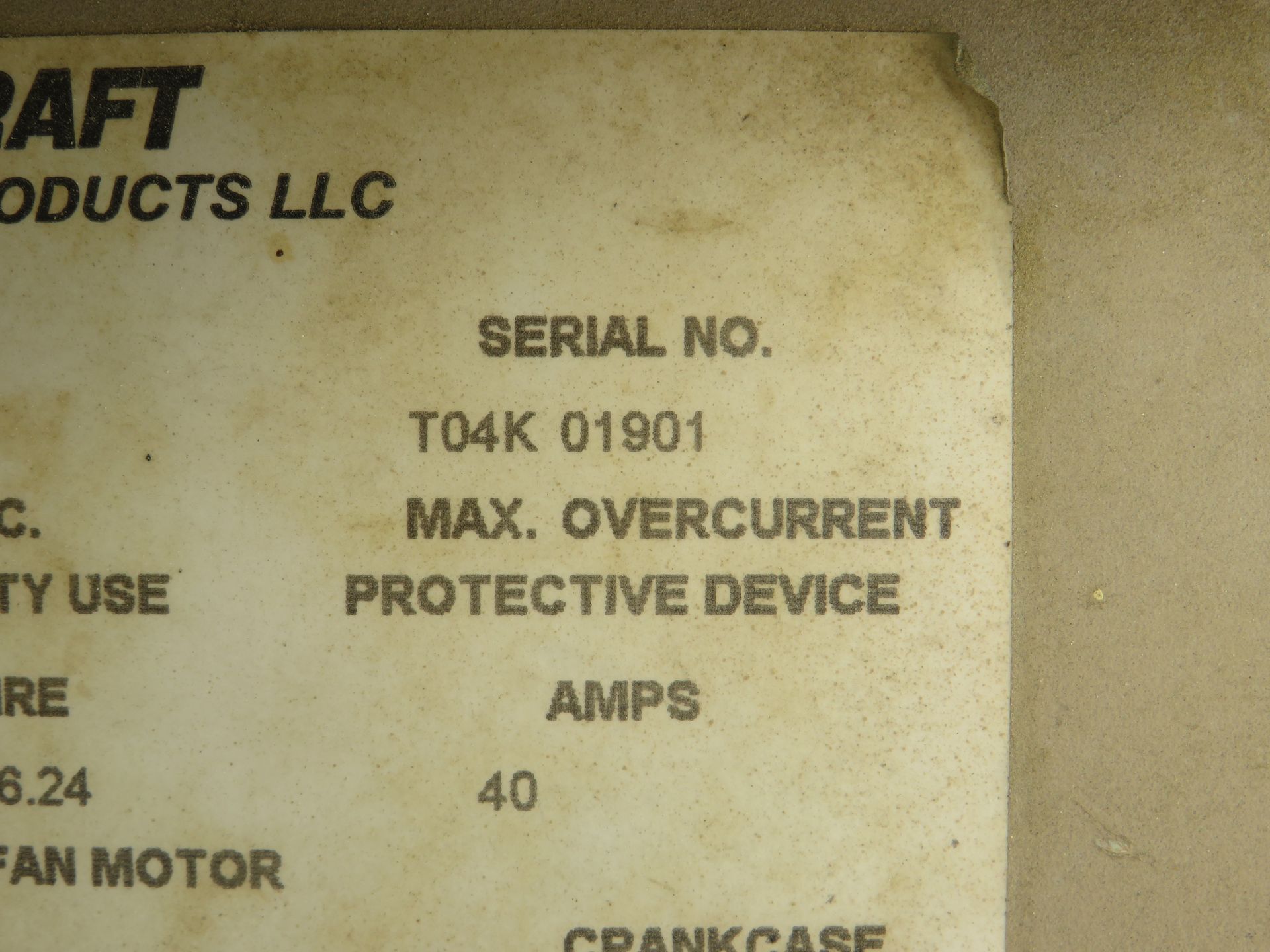

- Heatcraft BDT1000H2D Remote Chiller; s.n. TO4K01901; 460V; 3 PH

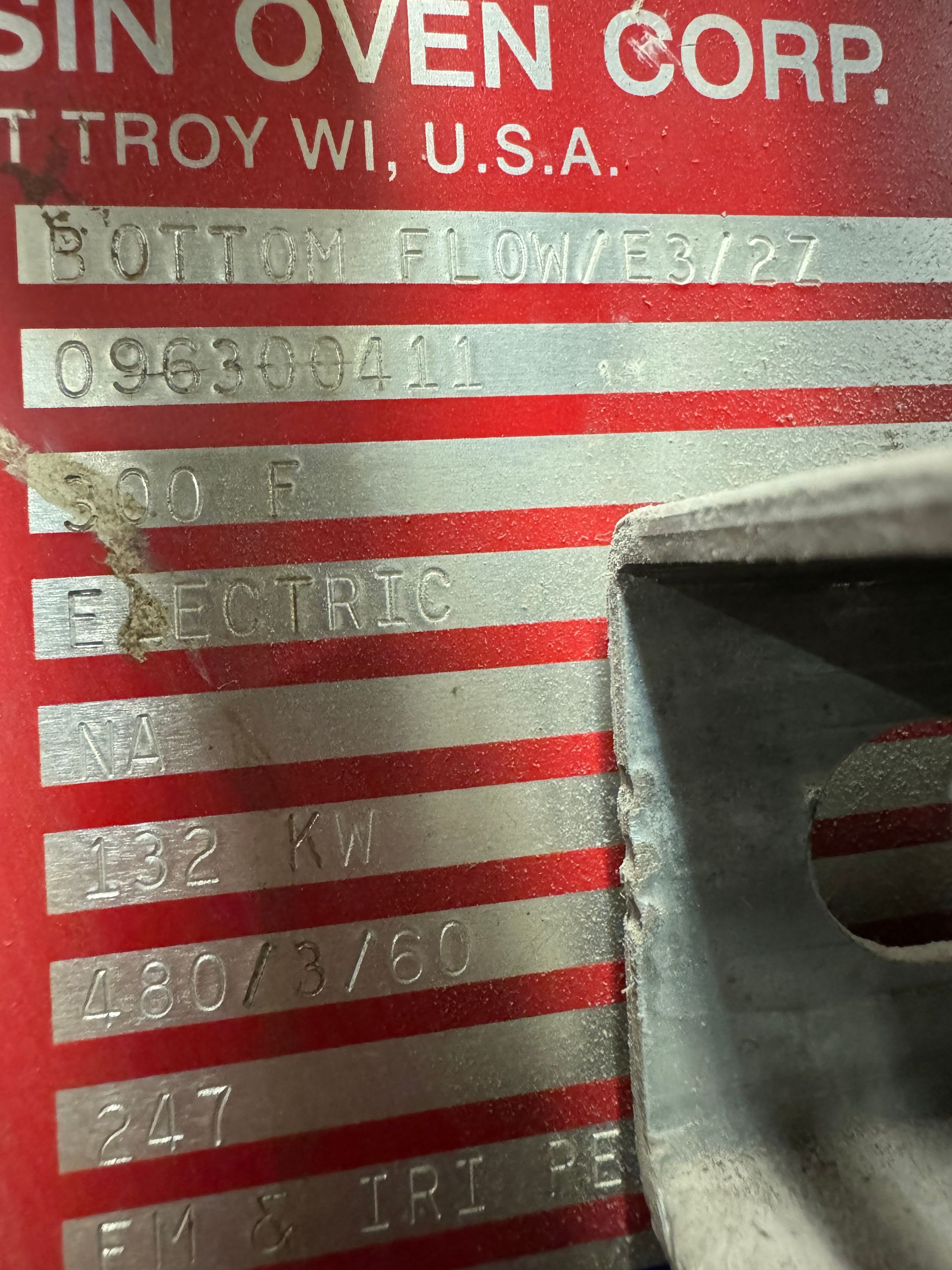

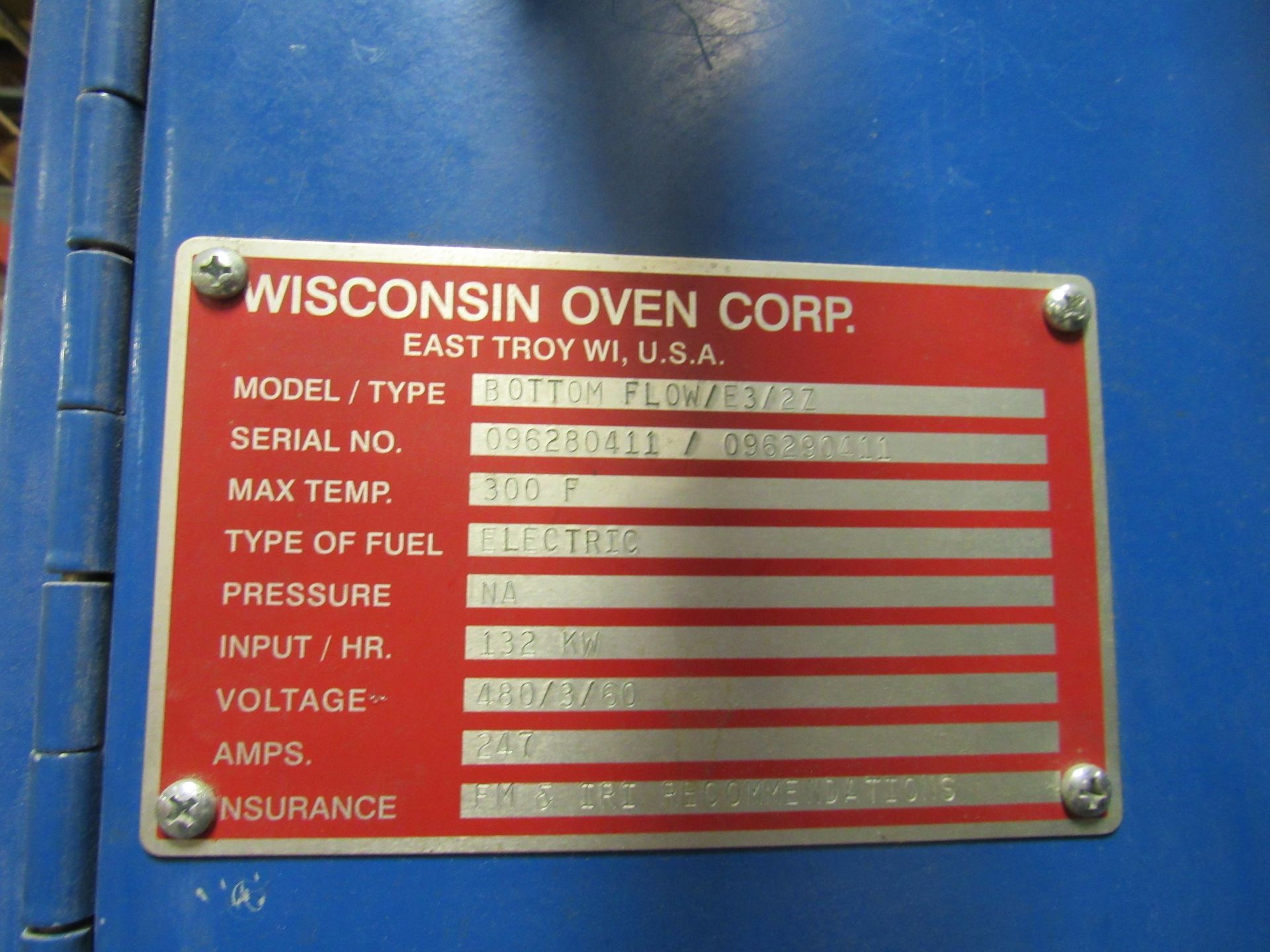

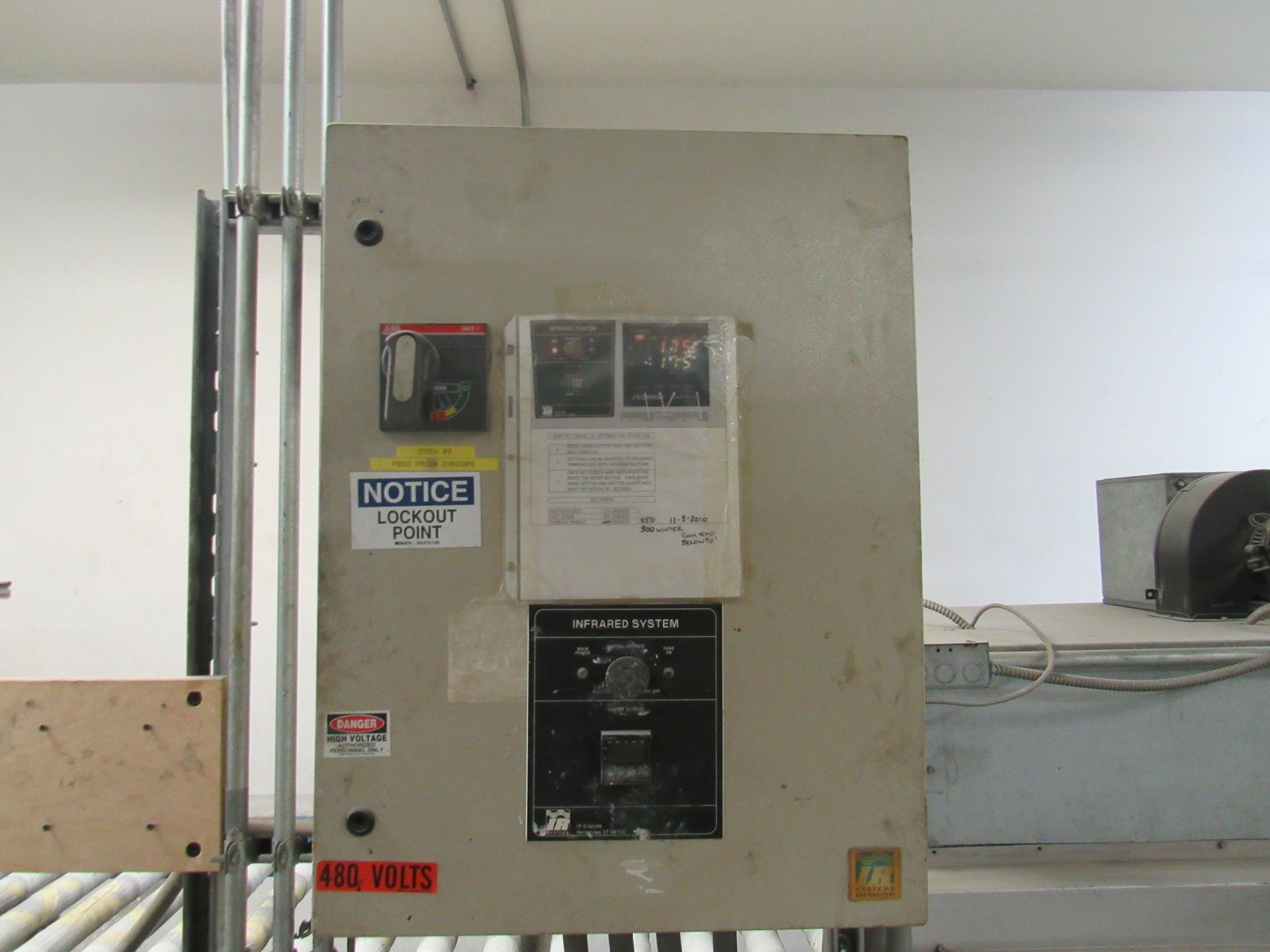

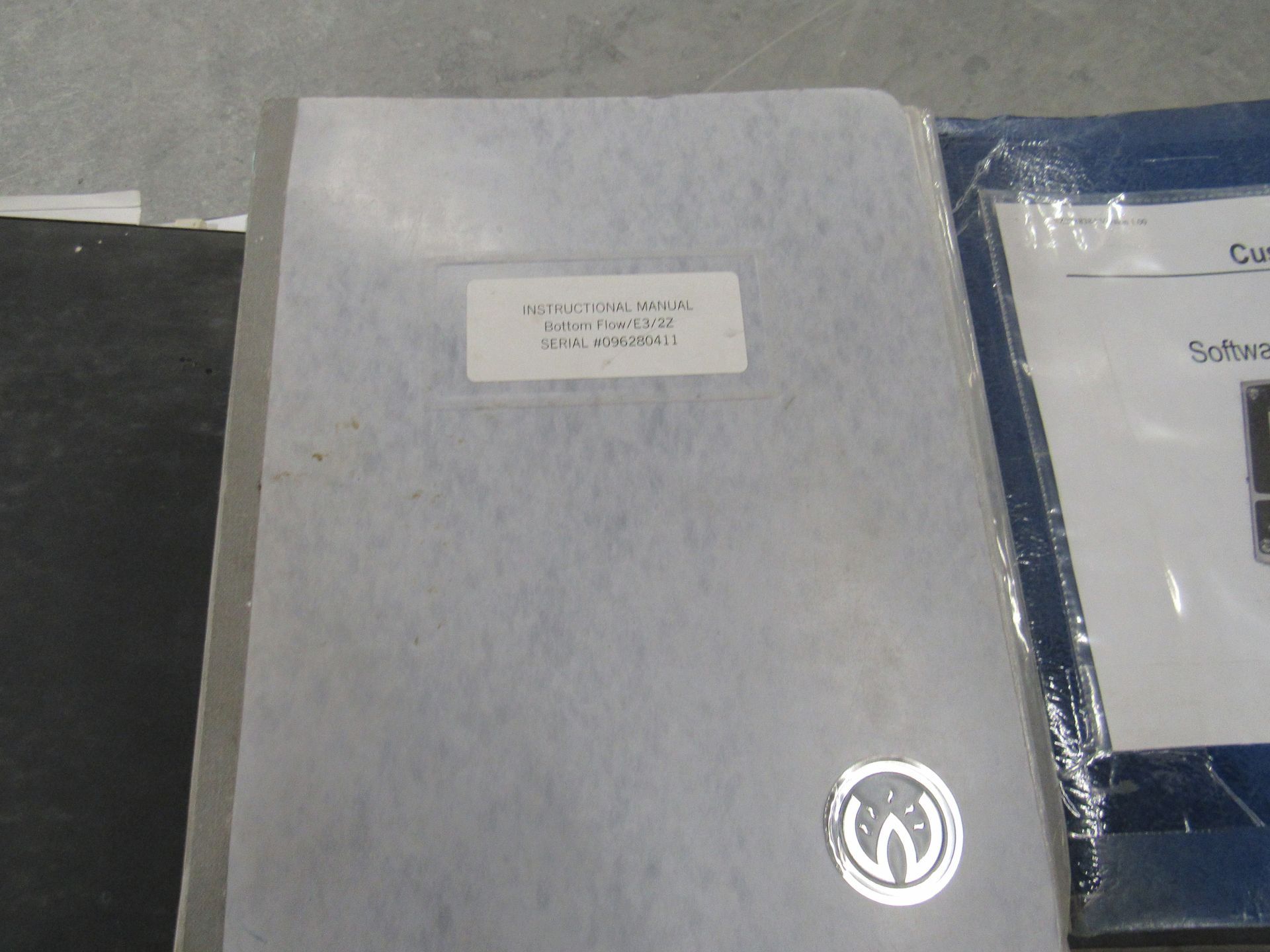

- Wisconsin Bottom Flow E3/2Z Control Panel; s.n. 096300411; 480V; 3 PH

- Multi-Unit Electric Control Cabinet

- Lewco Belt Conveyor; 30"x 56"; 208-230/460V; 3 PH

- Omega Four Head IR Heater; 240Vx480V transformer; 1 PH

- Single Head Fully Traversing Gantry Spray Booth with regulator; over Bilt-Rite 30" x 7' wire conveyor; 208-230/460V; 3 PH

- Argus International 4820FC Four Zone Long Wave IR Final Cure Oven; 480V, 3 PH

- (20) Pan Carts & (240) Pans

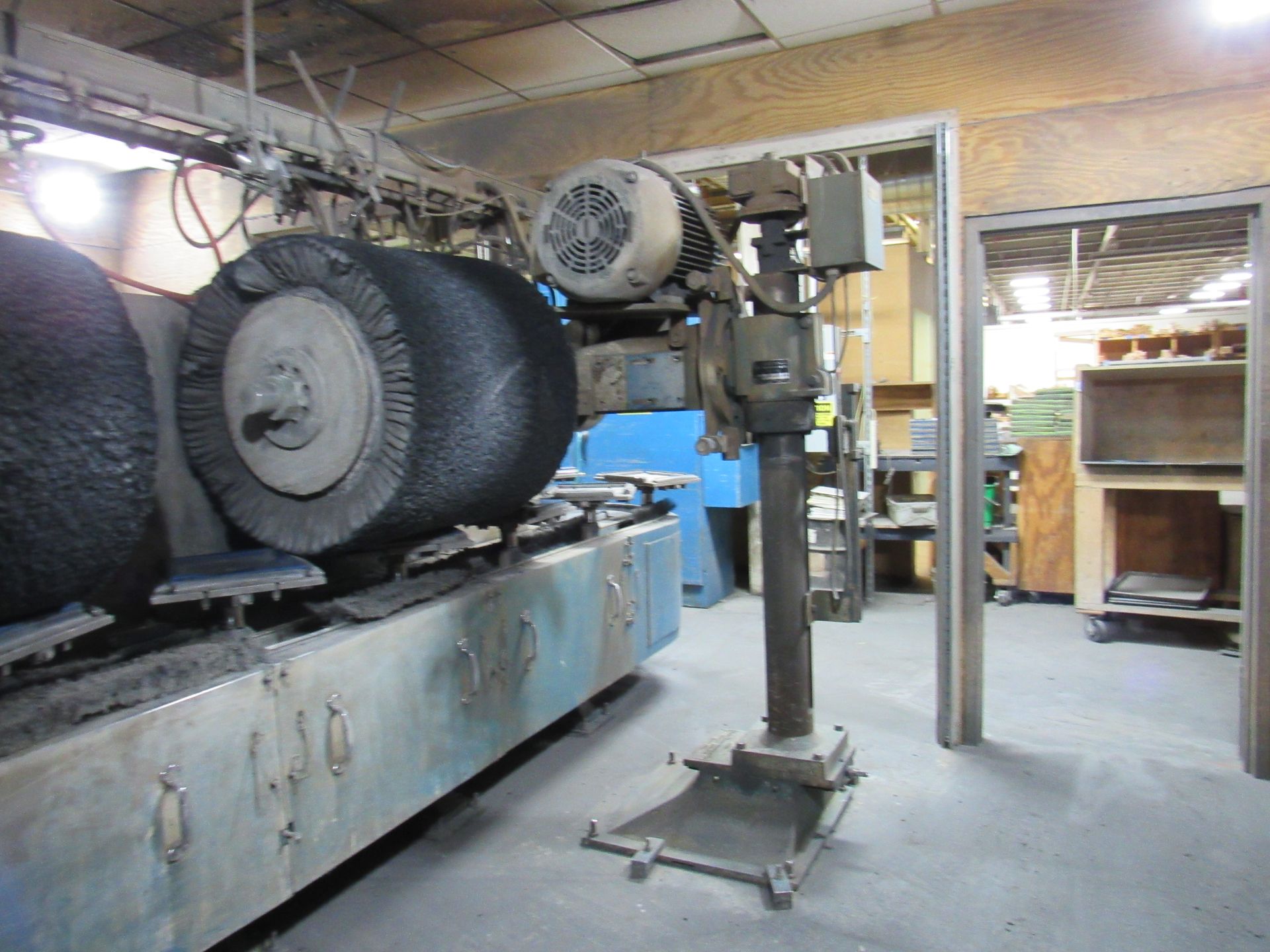

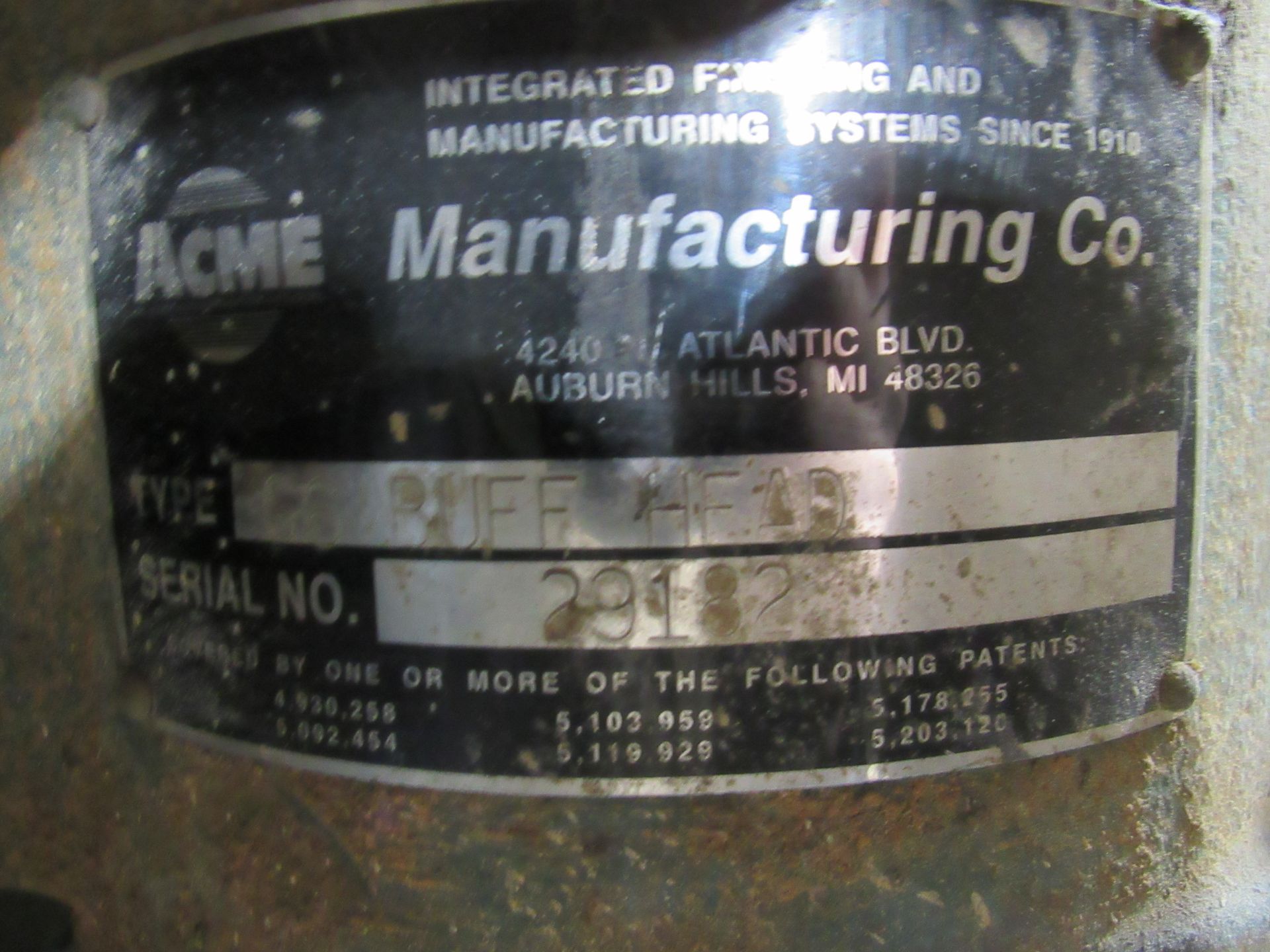

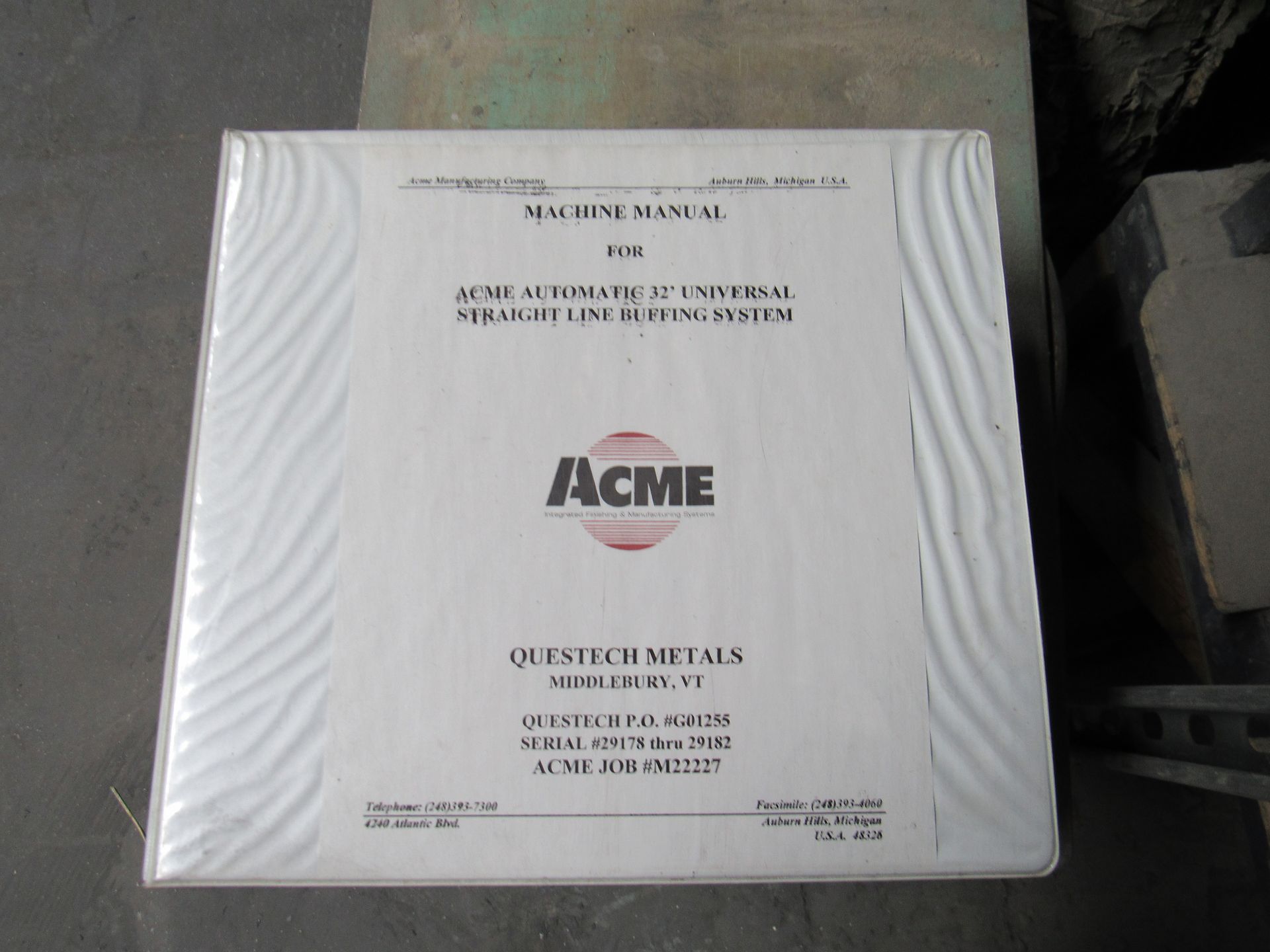

- ACME Four Head 16 Station Rotary Buffing Machine with enclosure; s.n. 29179-82; (4) Acme G6 25 HP buffing heads; 480V; 3 PH;

- Lewco Power Roller Conveyor; 30" x 22'; 208-230/460V; 3 PH

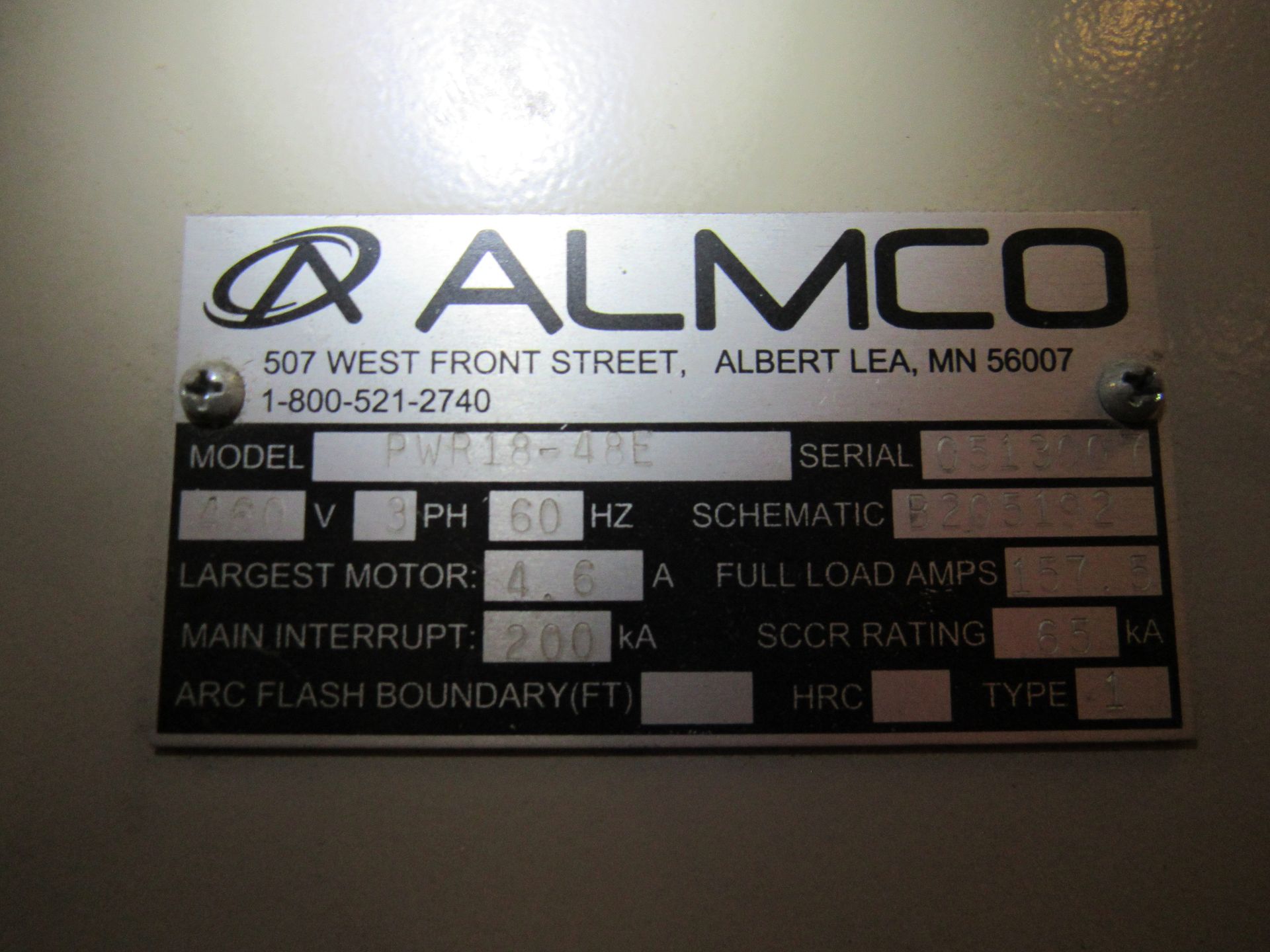

- ALMCO PWR18-48E Wash Point; with heated tanks and recirculator; with ALMCO control panel; 460V, 3 PH

- Six Head Air Knife with VDF Blower Control; 15 HP; 230/460V; 3 PH

- Lewco Power Roller Conveyor; 30" x 16'; 208-230/460V; 3 PH

- Two Head Fully Traversing Gantry Spray Booth with(2) regulators; over Bilt-Rite 30" x 8' 6" wire conveyor; 208-230/460V; 3 PH

- Lewco Power Roller Conveyor; 30" x 9'; 208-230/460V; 3 PH

- Three Stage IR Heater; 1 PH; over Bilt-Rite 30" x 14' 6" wire conveyor; 208-230/460V; 3 PH

- SPDI UV Curing System; 480V; 3 PH; over Lewco Wire Mesh Belt Conveyor; 30" x 5'; 208-230/460V; 3 PH

- Lewco Power Roller Conveyor; 30" x 4' 6"; 208-230/460V; 3 PH

- Two Head Fully Traversing Gantry Spray Booth with(2) regulators; 30" x 8' 9" wire conveyor

- Lewco Power Roller Conveyor; 30" x 4' 6"; 208-230/460V; 3 PH

- Lewco Wire Mesh Belt Conveyor; 30" x 5'; 208-230/460V; 3 PH

- Lewco Power Roller Conveyor; 30" x 38'; 208-230/460V; 3 PH

Line does not include: compressed air system;

dust collection or make up air; fire suppression.

Specifications are not guaranteed, incl.: elecrtric phase, volts and amperage; speeds; dimensions; tempurature ranges; weights; capacities; patent and trademark numbers & status.

Lot 2

Semi-Automated Cast Resin "Stone" Production Line

Complete operating line to produce stone finish cast resin products, most recently being tiles and small bathroom fixtures, comprised of:

- JustRite 4x55 gallon Outdoor Rated Flammables Cabinet

- Flammables Storage Cabinet; 34" x 34" x 65"

- Advanced Process Technology ECS Series Polyester Resin Processor; s.n. EC3005; 240V, 3 PH

- Super Sack Rack with hopper on Lift25K Lift Table

- APT 30-10 Pneumatic Feed on steel rack

- 400# Jacketed Primary Mix Tank

- 400# Jacketed Dispensing Tank

- TruTemp 200/10K BTU Chiller, 208V, 1 PH

- (2) APT SPPM-3006 Dual Piston Pumps

- APT M-C 3004 Dispensing System on dual head 3 axis gantry with static mixers and binary code mold reader (with option for continuous movement or lockdown dependent on mold volume)

- Wisconsin Conveyor Oven; 5' x 26' wire mesh belt; 480V; 3 PH; 1.9-2.35 fpm belt speed; 300° F max temp; with blower

- (4) Activated Charcoal Carbon Beds for styrene removal

- Lewco Power Roller Conveyor; 5' x 7' 6"; 208-230/460V; 3 PH

- Roller Ball Table (where product is removed from molds)

- Lewco 90° Power Roller Return Conveyor; 26"; 208-230/460V; 3 PH

- Single Head Fully Traversing Gantry Spray Booth with regulator (mold release); over Bilt-Rite 30" x 7' wire belt conveyor; 208-230/460V; 3 PH

- Wisconsin Conveyor Chiller with air knife; 30" x 28' wire mesh belt; 7 fpm max. speed (to bring molds down to fillable tempurature and conveyance back to filling station)

- Heatcraft BDT1000H2D Remote Chiller; s.n. TO4K01901; 460V; 3 PH

- Wisconsin Bottom Flow E3/27 Control Panel; s.n. 096280411/091290411; 480V; 3 PH

- Lewco Belt Conveyor; 26' x 7' 9"; 208-230/460V; 3 PH

- Omega Two Head IR Heater; 240Vx480V transformer; 1 PH

- Two Head Fully Traversing Gantry Spray Booth with (2) regulators; over Bilt-Rite 30" x 12' wire belt conveyor

- Four Head IR Top Surface Heater

- Variable Speed Incline to Flat Belt Conveyor; 24" x 46'; 230/460V; 3 PH

- Lewco Incline Belt Conveyor; 24" x 20'; 230/460V; 3 PH

- Lewco Roller Conveyor; 24" x 6'; non-motorized; with tip up walk through

- Lewco Power Roller Conveyor; 30" x 30'; 208-230/460V; 3 PH

- Lewco 90° Power Roller Conveyor; 30"; 208-230/460V; 3 PH

- Bilt-Rite Poly Mesh Belt Power Conveyor with water rinse and drain; 30" x 11' 9"; 208-230/460V; 3 PH

- Six Head Air Knife with VFD blower control; 15 HP; 230/460V; 3 PH

- Lewco Power Roller Conveyor; 30" x 26'; 208-230/460V; 3 PH

- Two Head Fully Traversing Gantry Spray Booth with (2) regulators; over Bilt-Rite 30" x 8' 9" split wire belt conveyor; 208-230/460V; 3 PH

- Lewco Power Roller Conveyor; 30" x 4' 6"; 208-230/460V; 3 PH

- Three Stage IR Heater; 240Vx480V transformer; 1 PH; over Bilt-Rite 30" x 14" Wire Belt Conveyor; 208-230/460V; 3 PH

- Two Head Fully Traversing Gantry Spray Booth with (2) regulators; over Bilt-Rite 30" x 8' 9" split wire belt conveyor; 208-230/460V; 3 PH

- IR Systems Three Zone IR Curing Unit; 480V; 3 PH; over Lewco Power Roller Conveyor; 30" x 20'; 208-230/460V; 3 PH

- SPDI UV Curing System; 480V; 3 PH; over Lewco Wire Mesh Belt Conveyor; 30" x 5'; 208-230/460V; 3 PH

- Lewco Power Roller Conveyor; 30" x 38'; 208-230/460V; 3 PH

Line does not include: compressed air system;

dust collection or make up air; fire suppression.

Specifications are not guaranteed, incl.: elecrtric phase, volts and amperage; speeds; dimensions; tempurature ranges; weights; capacities; patent and trademark numbers & status.

Lot 3

Formula 131 IP and Inventory

Marketing:

- Website - www.formula131.com

- Social Media Accounts

- YouTube Videos

- Marketing Collateral

- Application Instructions

- Packaging

Trademarks of Formula 131 Logo:

- United States Trademark Registration Number 67726377

- EU, Brazil, and Madrid Inernational Registration No. 1625707

- Hong Kong International Registration No. 305752972

Patents:

- United States Patent No. US 2021/0253890 A1

- International Patent No. PCT/US2021/070112

- European Patent Appl. No. 21754463.4 │ PA Ref. No. QUE-2012EP01

Inventory (subject to change):

- (21) 1000 Gram Installation Kits (FORMULA 131 PART A-60 SF Kit-750 grams/ 1.65 lbs + FORMULA 131 PART B-60 SF Kit-250 grams / 0.55 lbs.)

- 1200 lbs of FORMULA 131 PART A Compound

- 602 lbs of FORMULA 131 PART B Compound

Lot 4

Questech Corporation IP

Marketing:

- Website - www.questech.com

- Social Media Accounts

- YouTube Videos

- Marketing Collateral, incl. Packaging Supplies

- Application / Installation Instructions

Trademarks:

- United States Trademark Registration Number 3268039

- United States Trademark Registration Number 2681464

- United States Trademark Registration Number 3254330

- United States Trademark Registration Number 1655986

- United States Trademark Registration Number 2559142

Patents:

- United States Patent No. US 8323749 B2

- United States Patent No. US 8999507 B2

- United States Patent No. US D688935 S

- United States Patent No. US D732375 S

- United States Patent No. US D823616 S

- United States Patent No. US 10532956

- United States Patent No. US 11739234

- European Patent Convention and Italy No. 3665017

Specifications are not guaranteed, incl.: elecrtric phase, volts and amperage; speeds; dimensions; tempurature ranges; weights; capacities; patent and trademark numbers & status.